7

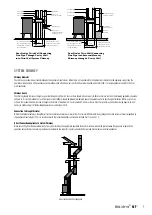

SYSTEM CHIMNEY

Chimney Diameter

The chimney size should be as recommended by the appliance manufacturer. Where there is a requirement for a flue

diameter smaller than the appliance spigot, then the operational requirements of the appliance and the configuration of

the flue must satisfy the flue sizing requirements of EN13384-1 for single appliances, and EN13384-2 for multi appliances.

Chimney Route

The chimney should remain as straight as possible through its vertical run to assist flow. Should it be necessary to offset

a chimney run then the following guidelines should be adhered to:

It is recommended that a vertical run of at least 600mm should be allowed immediately above the appliance prior to

any change of direction. Within a system, on all fuels, there should be no more than 4 changes of direction of maximum

45°. Factory made 90° bends or tees within the system may be treated as being equal to two 45° bends (as per

Document J of the Building Regulations issued October 2010).

Connection to Draught Diverter

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm

before any change of direction (unless otherwise specified by the appliance manufacturer). This is in accordance with

the recommendations contained in BS 5440 Part 1 section 6.1.4

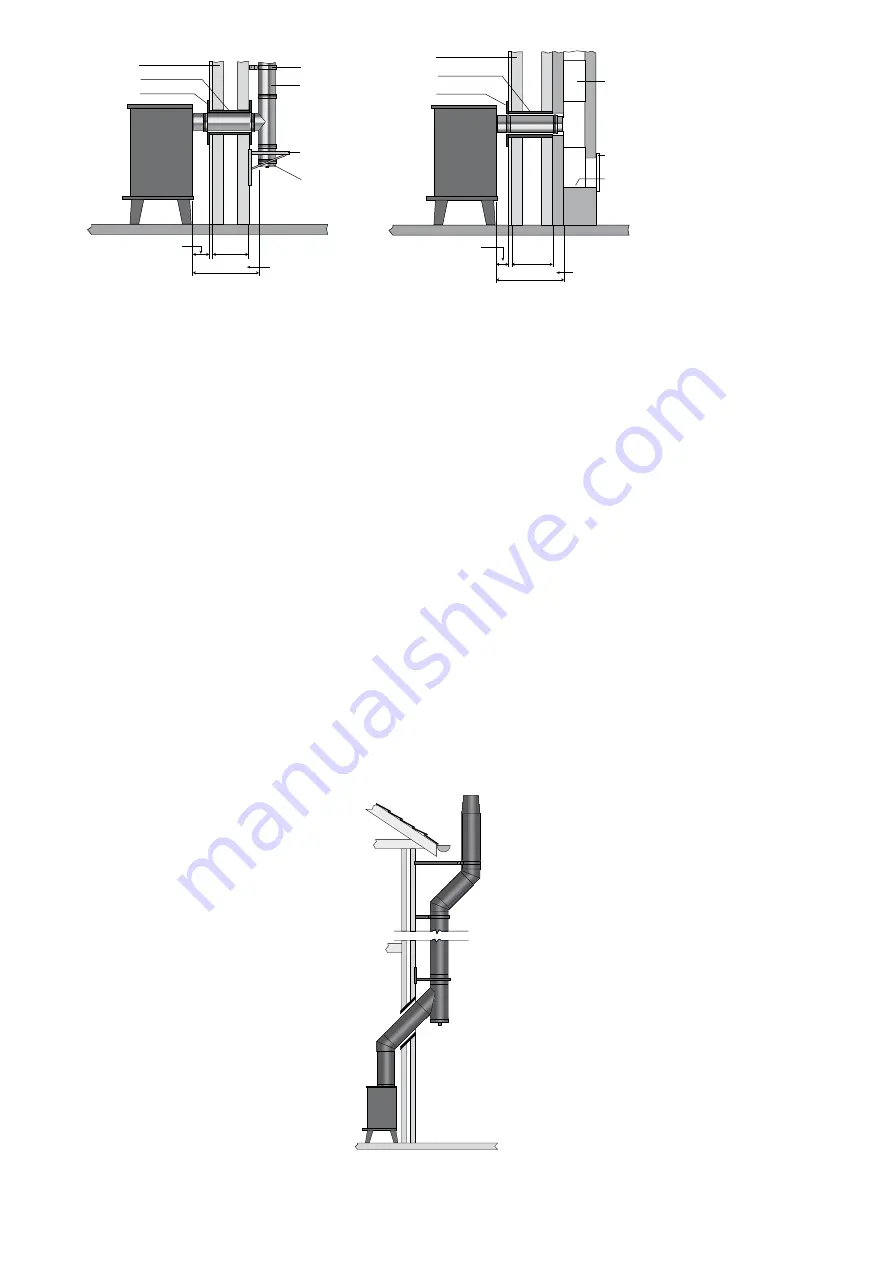

Direct Connection Appliance to System Chimney

When connecting from the appliance directly to a system chimney, the appropriate appliance connector must be used

and the joint between the appliance spigot and the appliance connector must be securely caulked and sealed with non

asbestos rope (or suitable alternative) and fire cement on solid fuel appliances.

ICID Plus direct connection

from appliance.

6

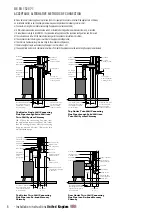

Top Outlet Twin Wall Connecting

Flue Pipe into Re-lined Masonry

Chimney

Rear Outlet Twin Wall Connecting

Flue Pipe Through Cavity Wall

into Twin Wall System Chimney

Rear Outlet Twin Wall Connecting

Flue Pipe into Re-lined Masonry

Chimney

Rear Outlet Twin Wall Connecting

Flue Pipe into External Masonry

Chimney through a Cavity Wall

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of appliance to outside

surface of chimney

Measured from back

of appliance to liner

of masonry chimney

Twin Wall

Chimney System

300

Wall Support

Tee Cap for

Debris Collection/

Cleaning Access

Wall Sleeve

Trim Collar

Cavity Wall

Wall Band

450mm MAX

300

450mm MAX

External Masonry

Chimney System

Inspection/

Cleanout Door

Cavity Wall

Wall Sleeve

Trim Collar

Debris

Collector

Wall Sleeve

Trim Collar

100

100

225 square

(9” x 9”)

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from

back of appliance

to flue liner

Wall Support

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Wall Band

450mm MAX

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

225

Wall Support

Wall Band

450mm MAX

600 min

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Support Bracket

Tee Piece

Tee Cap for

Debris Collection/

Cleaning Access

Single Wall to

Flex Connector

225 square

(9” x 9”)

450mm

MAX

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of connecting flue pipe

to flue liner

No further

bends allowed

on this

configuration

600 min

100

100

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of appliance to outside

surface of chimney

Measured from back

of appliance to liner

of masonry chimney

Twin Wall

Chimney System

300

Wall Support

Tee Cap for

Debris Collection/

Cleaning Access

Wall Sleeve

Trim Collar

Cavity Wall

Wall Band

450mm MAX

300

450mm MAX

External Masonry

Chimney System

Inspection/

Cleanout Door

Cavity Wall

Wall Sleeve

Trim Collar

Debris

Collector

Wall Sleeve

Trim Collar

100

100

225 square

(9” x 9”)

Flexible Twin Wall

Chimney Liner

Chimney Wall

Support Bracket

Swept Elbow

Sweep access

Tee Piece

Single Wall to

Flex Connector

450mm

MAX

Measured from

back of appliance

to flue liner

Wall Support

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

600 min

225

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Wall Band

450mm MAX

Measured from back

of connecting flue

pipe to outside

surface of chimney

Tee Cap for

Debris Collection/

Cleaning Access

Twin Wall

Chimney System

Solid Wall

Inspection Bend

Wall Sleeve

Trim Collar

225

Wall Support

Wall Band

450mm MAX

600 min

For minimum distance for

this configuration check

manufacturers distance

to combustibles

No further

bends allowed

on this

configuration

Flexible Twin Wall

Chimney Liner

Inspection/

Cleanout Door

Inspection Bend

Wall Sleeve

Trim Collar

Chimney Wall

Support Bracket

Tee Piece

Tee Cap for

Debris Collection/

Cleaning Access

Single Wall to

Flex Connector

225 square

(9” x 9”)

450mm

MAX

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

For minimum distance for

this configuration check

manufacturers distance

to combustibles

Measured from back

of connecting flue pipe

to flue liner

No further

bends allowed

on this

configuration

600 min

100

100

SYSTEM CHIMNEY

Chimney Diameter

The chimney size should be as recommended by the appliance manufacturer� Where there is a requirement for a flue diameter smaller than the appliance spigot, then the

operational requirements of the appliance and the configuration of the flue must satisfy the flue sizing requirements of EN13384-1 for single appliances, and EN13384-2 for

multi appliances�

Chimney Route

The chimney should remain as straight as possible through its vertical run to assist flow� Should it be necessary to offset a chimney run then the following guidelines should be

adhered to: It is recommended that a vertical run of at least 600mm should be allowed immediately above the appliance prior to any change of direction� Within a system, on

all fuels, there should be no more than 4 changes of direction of maximum 45°� Factory made 90° bends or tees within the system may be treated as being equal to two 45°

bends (as per Document J of the Building Regulations issued October 2010)�

Connection to Draught Diverter

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm before any change of direction (unless otherwise specified by

the appliance manufacturer)� This is in accordance with the recommendations contained in BS 5440 Part 1 section 6�1�4

Direct Connection Appliance to System Chimney

When connecting from the appliance directly to a system chimney, the appropriate appliance connector must be used and the joint between the appliance spigot and the

appliance connector must be securely caulked and sealed with non asbestos rope (or suitable alternative) and fire cement on solid fuel appliances�

direct connection from appliance

7

Metaloterm

®

MF

-