Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

9 Maintenance

9

Maintenance

WARNING: All maintenance work may only be performed with the actuator disconnected from the power

supply.

CAUTION:

Due to this requirement, the actuator has to be in the Failsafe position!

NOTE:

If this is not the case, it may be because of a fault in the fitting (stuck valve stem).

WARNING: The actuator has a pre-loaded coil spring or a disk spring assembly! When loosening the

flange mounting bolts, the spring force against the valve can cause the actuator to come loose from

the valve. Adequate safety measures must be taken!

WARNING: Any powering up must be ruled out during maintenance! Work on the electrical systems

or components may only be carried out by electricians or by individuals, who have been instructed

how to do so, working under the guidance and supervision of an electrician in accordance with electro

technical regulations.

After completing their commissioning, the actuators are ready for use. The actuator is filled with oil as standard when

shipped.

Routine checks:

• Be mindful of increased running noises. In cases of long down times, operate the actuator at least every three

months.

• Check the Failsafe function (check the operating time and smoothness of running in Failsafe operation). Lengthening

in the running time may also be caused by an increased torque requirement for the fitting after long down times.

WARNING: The actuator has a pre-stressed coil spring or disk spring assembly. Improper dismounting

may lead to both damage to the actuator as well as serious injuries! If maintenance work is needed re-

quiring the actuator to be dismounted, contact SCHIEBEL Antriebstechnik GesmbH regarding detailed

instructions and/or any special-purpose tools for relaxing the spring assembly!

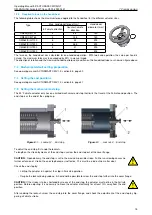

The actuators are designed for any mounting position (See section 4.3, page 7), which is why there is neither a filling level

indicator nor a drain plug on the main casing.

Depending on the stressing subjected to, do the following approx. every 10,000 to 20,000 hours (about 5 years; see

section 12, page 18):

• Oil change

• Replace seals

• Check all the roller bearings and the worm gear assembly and replace if necessary.

Take the types of oils and greases to be used from our lubricant table. (See section 12, page 18)

NOTE:

Check the cable glands at regular intervals (annually) for tightness of the cables and retighten if necessary.

If the visual inspection indicates that the effectiveness of the sealing elements of the cable entry has suffered damage

or aging effects (e.g. dust or water penetration), such elements have to be replaced, preferrably using the original spare

parts from the manufacturer of the equipment. or through cable entries of comparable quality as well as the same ex- or IP

protection class.

19