12

e

e

a

a

X

X

BOILER INSTALLATION

Statutory requirements

The installation of this boiler must be carried out by

a qualified registered person in accordance with

the relevant requirements of the current issue of:

The Gas Safety (Installation and Use) Regulations

The Building Regulations

The local water company Byelaws

The Building Standards Regulations (Scotland)

The Health and Safety at Work Act

Sheet metal parts

WARNING. When installing or servicing this boiler,

care should be taken when handling the edges of

sheet metal parts to avoid the possibility of personal

injury.

Installing the boiler

Prior to starting work, the system must be thoroughly

flushed using a propriety cleanser such as

Sentinel

X300

to eliminate any foreign matter and contami-

nation e.g. metal filings, solder particles, oil, grease

etc.

Note

. Solvent products could cause damage to the

system.

●

Engage boiler upper part onto the hanging

bracket.

●

Fit the washers between the boiler pipes and the

inlet and outlet fittings on the fixing jig and con-

nect the various couplings between the boiler and

jig.

FLUE INSTALLATION

Top outlet flue - kit 85090

The boiler is only suitable for top outlet flue

connection.

Rear flue systems

The calculate the lenght when flueing to the rear

measure

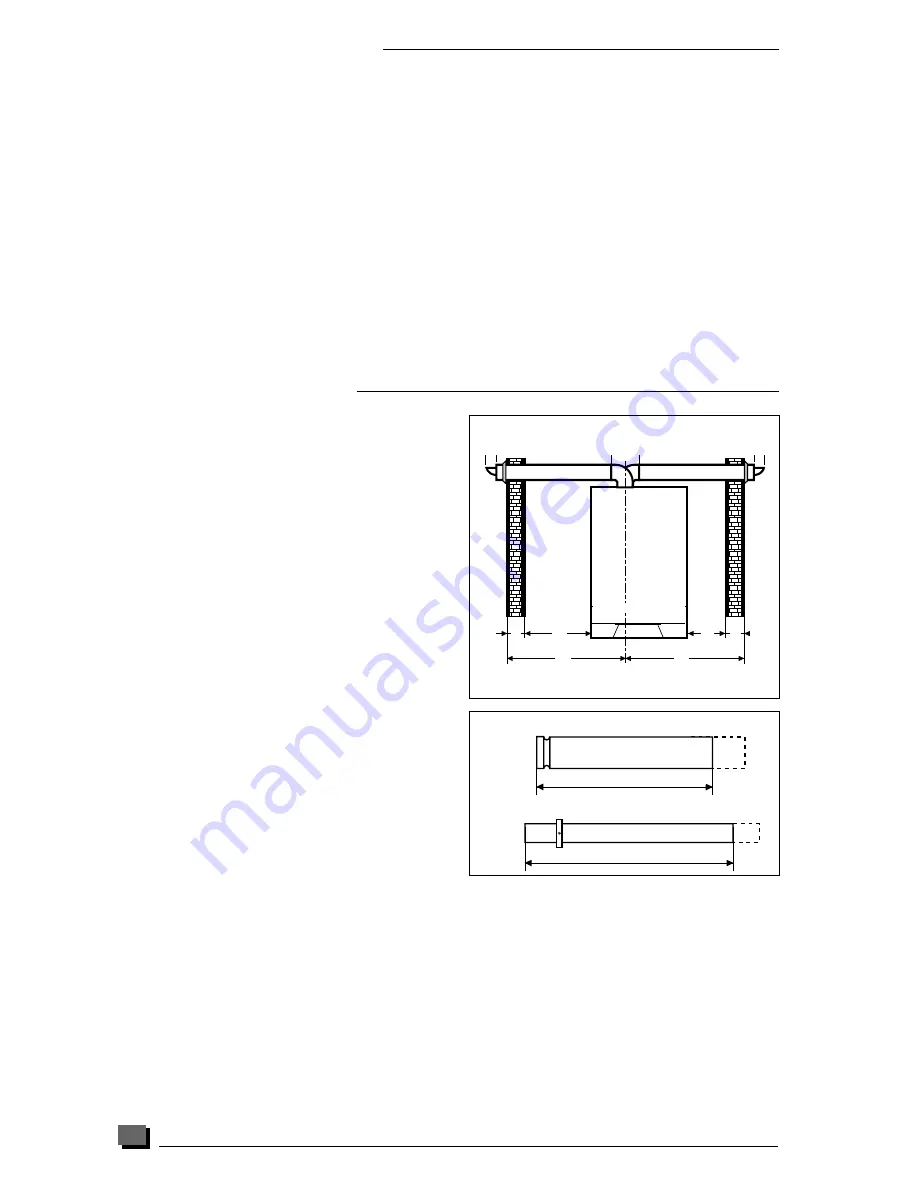

e (diagram 11)

plus 25 mm outer flue pipe

and

e

plus 125 mm to inner pipe measurement.

Calculation of cutting lengths when flueing to the

right or left

●

Measure wall thickness

e

(mm),

see diagram 11.

For right hand applications

●

Measure distance from inside face of wall to side

of the boiler

a (diagram 11)

add 350 mm to outer

pipe measurement and 445 mm to inner pipe

mesurement.

For left hand applications

●

Measure distance from inside face of wall to side

of the boiler

a (diagram 11)

subtract 25 mm for

outer pipe length and add 75 mm to inner pipe

length measurement.

●

Refer to

table 2

for cutting lengths of both inner

and outer flue pipes for each of the various flue

options available.

Important

: All flue cutting lengths must be meas-

ured from the terminal end of the flue pipes,

see

diagram 12.

When the dimension

X

measured on site is greater

than that given in

table 2

. Extensions will be required

as necessary.

Important:

All cutting lengths should be measured

from the push fit joint end of the extension pipe.

Do not leave any burrs or sharp edges on the cut

ends of the pipes.

Note :

maximum horizontal flue lenght without

bends is 3 m.

Table 2

Flue cutting lengths (mm)

Rear flue

Outer pipe : e + 25,

inner pipe : e + 120

Comment : maximum distance 'x' without extension 770 mm

Right side flue

Outer pipe : e + a + 350, inner pipe : e + a + 450

Comment : maximum distance 'x' without extension 515 mm

Left side flue

Outer pipe : e - 25,

inner pipe : e + 125

Comment :

maximum distance 'x' without extension 1087 mm

Hab 210a

Diagram 11

V

en 089

Diagram 12

Cutting length

Outer pipe

Inner pipe

Cutting length