- 24 -

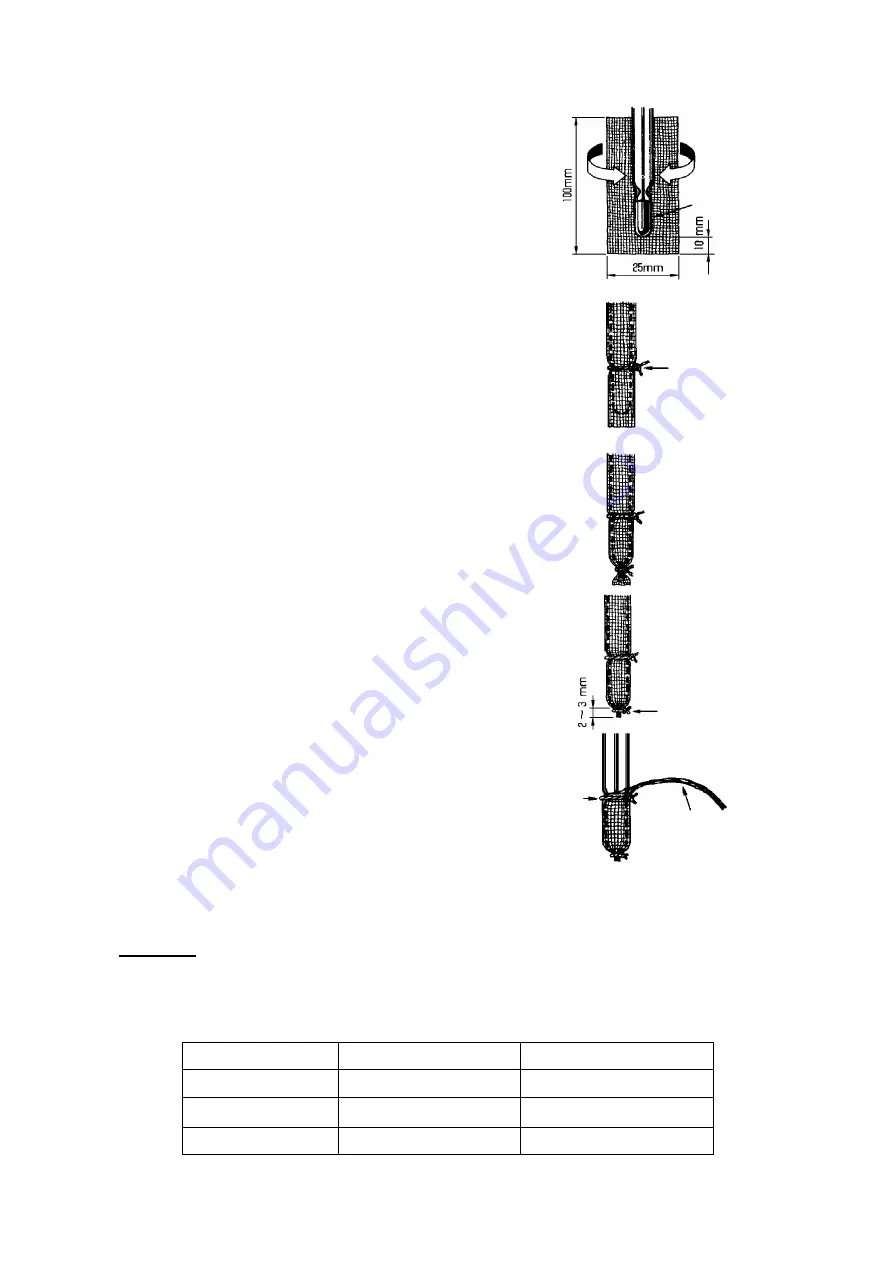

3. Cut a piece of gauze large enough to fit around the bulb

(100 x 25 mm), and dampen it with distilled water. Extend

the gauze about 10mm from the end of the bulb, and wind

the gauze around the sensing part without making wrinkles.

4. Use cotton thread to tie the gauze firmly around the

sensing part.

(about 30mm from the tip of the bulb)

5. Tie of the end of the gauze with another piece of tread. The knot

should be snug.

6. Cut off the gauze about 2 or 3 mm beyond the end of the

sensing part.

7. Carefully pull out and remove the horizontal threads

(woofs) of gauze above the hollow of the sensing part,

leaving only the vertical strands (warps). Make a string by

binding the remaining wraps of gauze.

8. Put back the lower part of air intake tube, clamp, and insert the string into the water reservoir.

Follow steps 4, 5,

6 in “Replacing the wick”.

Cautions

●

On interval of water supply

Duration of continuous operation with a supply of water differs depending on the circumstances

where the instrument is used. Be careful about water level of feed water tank referring to the

following table 1. Refer to the following chart just for a rough standard.

Lower than 40%rh

Higher than 40%rh

Lower than 15

℃

about 20 hours

about 30 hours

15 to 35

℃

about 25 hours

about 35 hours

35 to 50

℃

about 15 hours

about 20 hours

Tie off the end

of the gauze

Cut off the

gauze

Make a string by

binding the

remaining warps

Knot

above

bulb

Bul

b

Use cotton thread

to the gauze

firmly