IntelliFlow 3 Liquid Installation Guide

5

875-3000-100 Rev A1

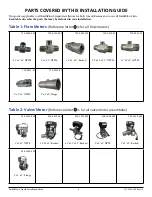

050-2509-000

G4 IF3 Cable

(1) (red cable)

Connects part I’s CONTROLLER

to G4’s FLOW port

050-2508-000

Bantam IF3 Cable

(1) (red cable)

Connects part I’S CONTROLLER to

Bantam’s FLOW port

054-0101-000

Power Cable

(1) (black and white cable)

Connects part I’s POWER cable to

aircraft power source, see item K

050-2503-000

IF3 Motor Cable

(1) (red cable)

Connects part I VALVE MOTOR to

valve/motor part B

050-2500-000

IF 3 Pre-amp Sensor Extension

Cable

(1) (red cable)

Connects part I FLOW METER to part N

050-2502-000

IF 3 Trim Pressure Switch Cable

(1) (red cable)

Connects part I’s TRIM/PRESSURE

cable to pressure switch part J and

optional pressure transducer part R

806-5002-000

IF3 Controller

(1) (blue box with 6 ports)

Liquid and Dry Controller

075-0035-222

Boom Pressure Switch

(1)

Detects Boom Pressure

424-0004-222

Power Switch/Circuit Breaker

(1, 10A)

Use with cable E, wire in with aircraft power

750-0110-03 (1”)

or

750-0109-03 (2”)

or

750-0107-03 (3”)

Aviation Hose

( 1x19.75 of 1”, 2” or 3”)

Use between spray valve and meter; meter

and valve; valve and boom. Attach with

part M.

682-1053-222 (2.25”)

or

682-1054-222 (2.75”)

or

682-1056-222 (3.75”)

Hose Clamp

(4 of 2.25”, 2.75”, or 3.75”)

Attach to Hose L

121-0004-000

3-Pin Flowmeter Sensor

(1)

Magnetic pick-up sensor to use with

flow meter part A

Kit #710-2001-000

Horizontal Mounting Bracket

(2)

Kit #710-2001-000

M4 Screw (4) - part Pa Bolt, 6-32 x 3/8” (8) - part Pd

Washer, split-lock (4) - part Pb Washer, (8) Pe

Vibration Isolator (4) - part Pc Nut, locking 6-32 (8) - part Pf

Use items as required for your specific installation

Kit #711-1001-01

IF System Control Label

(2)

Use with switch on part F

Kit #711-1001-01

Terminal Ring

(2)

121-0033-01

Pressure Transducer

(Optional, not included in kits)

If used, connect to cable H. Can set data

panel or lightbar to display the pressure

reading (option is ‘Primary Boom PSI’).

601-1313-000

(Optional, not included in kits)

Mounting Layout Template for

Falcon/IF3 Rack Mount

601-1317-000

(Optional, not included in kits)

Mounting Layout Template for

Falcon/IF3 Horizontal Mount

Table 3: IntelliFlow 3 Liquid Installation Parts