13

6.

6.

6.

6.

Quality Control

Quality Control

Quality Control

Quality Control

6.1

6.1

6.1

6.1

Inspecting weld quality

Inspecting weld quality

Inspecting weld quality

Inspecting weld quality

The BioWelder® is designed to make reproducible and reliable connections,

however it is still critical to inspect the weld prior to use.

Important:

Important:

Important:

Important:

Allow the weld to cool down for 2-3 minutes before inspection to achieve optimal

strength.

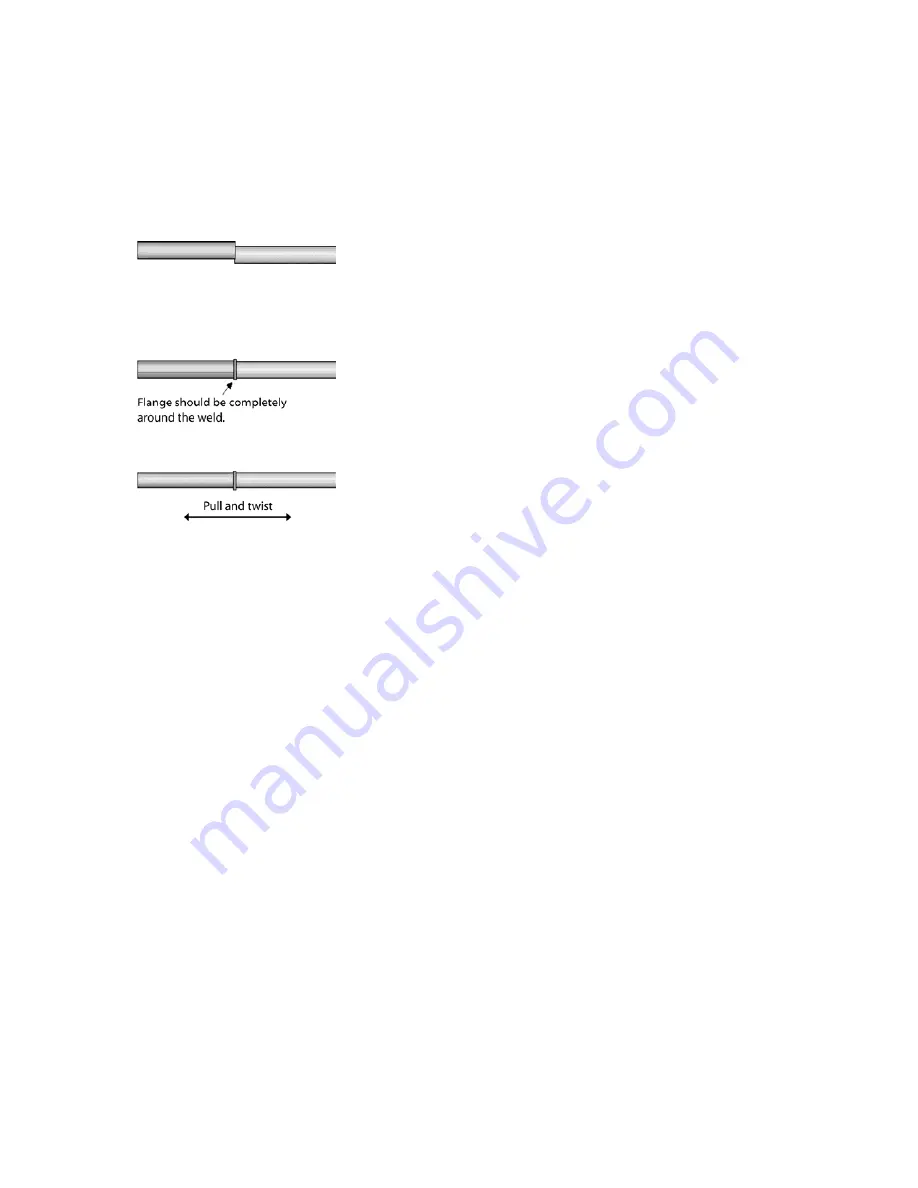

1. Axial alignment

Check that the tubing is axially aligned. If the tubing is offset, the weld will

be weaker on one side. Do not use such welds. Contact your Service

Representative to realign the unit.

2. Uniform weld

Check that you see a flange all around the weld. This indicates that the weld is

uniform in the radial direction. If you do not see a flange around the weld, discard

the weld. Make sure that you are using the correct tubing. If you are unable to get

a uniform flange contact your Service Representative for help.

3. Good tensile strength

Pull GENTLY at the weld. It should not come apart or start to crack

6.2

6.2

6.2

6.2

Using different

Using different

Using different

Using different types of hoses

types of hoses

types of hoses

types of hoses

It is possible to weld thermoplastic tubings like C-Flex®, Raumedic® FluiSoft

TM

,

Pharmed® and Sanipure®.

It is not possible to weld non-thermoplastic formulations such as PTFE, silicone,

or natural rubber. A list of compatible tubing is provided in the Appendix 2.

Different tube formulations have varying melt points. Most tubes can be joined

satisfactorily using the default settings.

Your machine is set to the tubes types

Your machine is set to the tubes types

Your machine is set to the tubes types

Your machine is set to the tubes types

you selected on your order.

you selected on your order.

you selected on your order.

you selected on your order.

6.3

6.3

6.3

6.3

Welding different parameters

Welding different parameters

Welding different parameters

Welding different parameters

The BioWelder® is capable of joining tubes of various outer diameters. A set of

tubes holders specific to each tubing outer diameter must be purchased. These

holders are available for a minimum tubing outer diameter (OD) of 1/4 inch to a

maximum tubing OD of 3/4 inch.

Each holder set consists out of two blue (left) and two red (right) tube holders.

All four holders must be changed as a set. Holders can simply be snapped in and

out. The machine reads the coded holders and runs the appropriate stored

program.