17

GB

• If tripped:

-

Turn off and lock out the unit.

- Correct the fault.

- Reset the circuit breaker.

Note:

The opening of circuit breaker

Q4

disconnects only the control part. In the event of maintenance/servicing, all circuits must

be disconnected by opening the main circuit breaker.

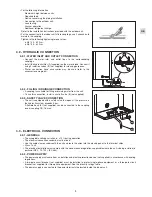

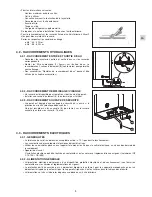

7.5 - TROUBLESHOOTING RECOMMENDATIONS

• All maintenance and servicing operations on the refrigerating circuit must be conducted in accordance with standard trade

practices and safety rules: recovery of the refrigerant, inert shielded (nitrogen) brazing, etc…

• All brazing operations must be conducted by qualified welders.

• For equipment charged with R 410 A, refer to the specific instructions in paragraph 4.1 and in the outdoor unit's manual.

• This unit is equipped with pressurised equipment, for example piping.

Use only genuine parts listed in the spare parts list for replacing defective refrigeration components.

• Pipes may only be replaced by copper tubing in compliance with standard NF EN 12735-1.

• Leak detection, in the case of pressure testing:

- Never use oxygen or dry air, as the risk of fire or explosion is present.

- Use dehydrated nitrogen or a nitrogen and refrigerant mix indicated on the manufacturer's plate.

- For units equipped with pressure gauges, the test pressure must not exceed the gauges' maximum allowable pressure

rating.

• All part replacement with other than genuine parts, all modifications of the refrigerating circuit, all replacement of refrigerant

by a fluid other than that indicated on the manufacturer's plate, all use of the unit outside the application limits defined in the

documentation, shall result in the cancellation of PED EC marking compliance which shall fall under the liability of the

individual who carried out these modifications.

• The technical information, relative to the safety requirements of the various applicable directives, is indicated on the

manufacturer's plate of the unit and mentioned on the 1

st

page of this manual.

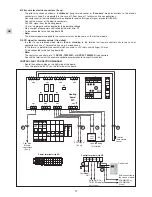

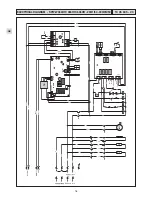

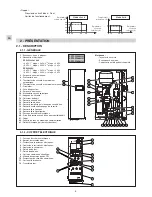

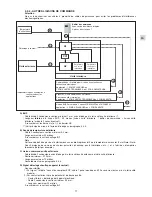

8 - WIRING DIAGRAM

A1

Heating control PCB

A2

Indoor unit PCB

CC1

Communication and control module

E1

Water pressostat

F1

Automatic - heater safety thermostat

F2

Manual - heater safety thermostat

J1

Water flow switch

KA1

Heater fault relay

KA2

Water flow relay

KM1

R1 contactor

KM2

R2 contactor

KM3

R3 contactor

KM4

M1 contactor

M1

Water circulator pump

Q1

R1 circuit breaker

Q2

R2 circuit breaker

Q3

R3 circuit breaker

Q4

Control circuit breaker

R1

Support heating element

R2

Support heating element

R3

Support heating element

S1

Water inlet temperature sensor (system)

S2

Water outlet temperature sensor

S3

Outdoor air temperature sensor

S4

Heat pump exchanger temperature sensor (E2)

S5

Liquid line temperature sensor (E1)

S6

Water return temperature sensor (Heat pump) (TA)

TR

Indoor unit board power supply transformer

Symbols of the components

BU

Blue

BK

Black

PK

Pink

RD

Red

WT

White

Colours of the wires

Summary of Contents for SPW-W366HH58

Page 19: ...19 GB ...

Page 37: ...19 FR ...