-30-

Electrical Adjustments

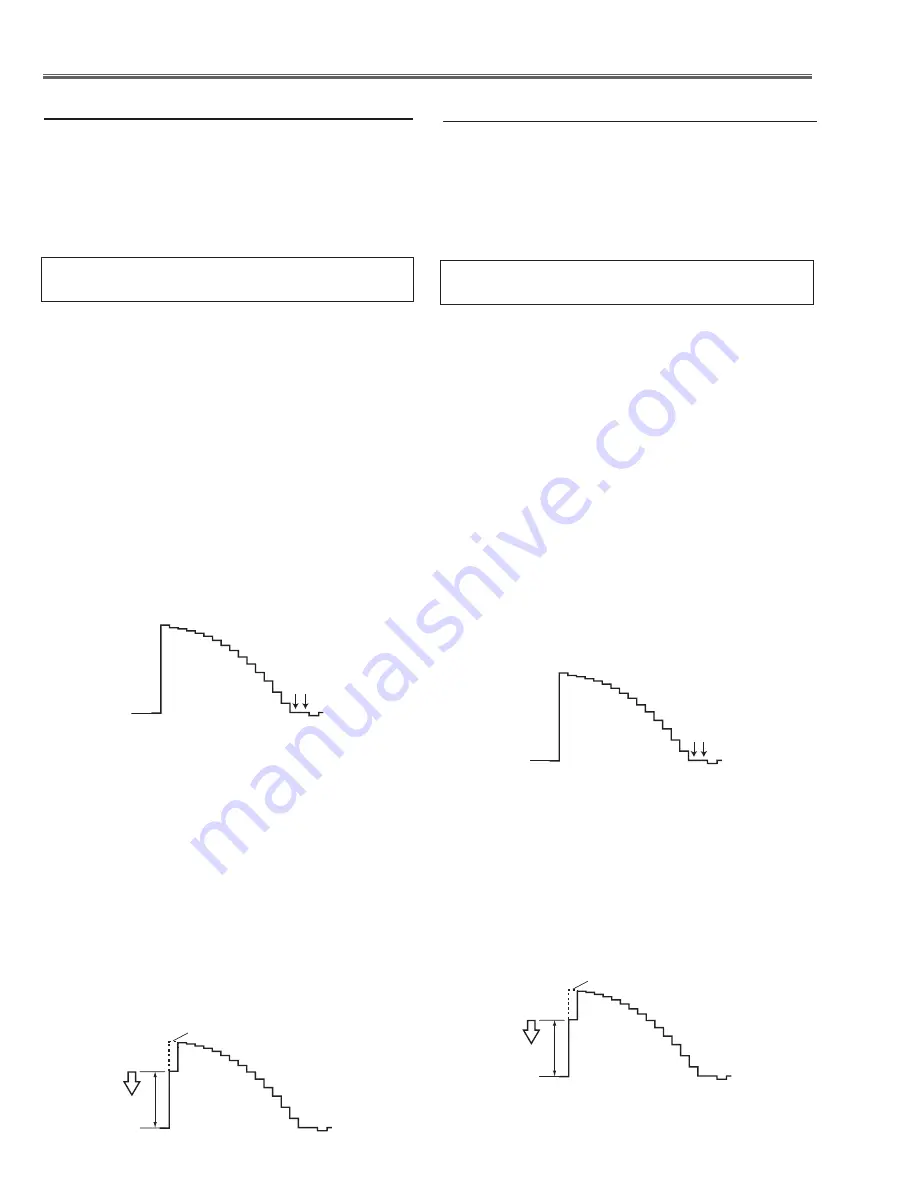

Gain adjustment [Pc]

1. Enter the service mode.

. Receive the 16-step grey scale computer signal with

computer1 [rGB]

mode.

3. Connect an oscilloscope to test point “

tP35G

” (+)

and chassis ground (-).

4. Select group no. “

0

”, item no. “

3

” and adjust the ampli-

tude “

a

” to be minimum by changing the Data value.

5. Connect an oscilloscope to test point “

tP35r

” (+)

and chassis ground (-).

6. Select group no. “

0

”, item no. “

4

” and adjust the ampli-

tude “

a

” to be minimum by changing the Data value.

7. Connect an oscilloscope to test point “

tP35B

” (+) and

chassis ground (-).

8. Select group no. “

0

”, item no. “

5

” and adjust the ampli-

tude “

a

” to be minimum by changing the Data value.

(a)

White Level

Pedestal adjustment [Pc]

1. Enter the service mode.

. Receive the 16-step grey scale computer signal with

computer1 [rGB]

mode.

3. Connect an oscilloscope to test point “

tP35G

” (+)

and chassis ground (-).

4. Select group no. “

0

”, item no. “

0

” and change data

value to adjust the pedestal level and black level to be

the same level.

5. Connect an oscilloscope to test point “

tP35r

” (+)

and chassis ground (-).

6. Select item no. “

1

” and change data value to adjust the

pedestal level and black level to be the same level.

7. Connect an oscilloscope to test point “

tP35B

” (+) and

chassis ground (-).

8. Select item no. “

2

” and change data value to adjust the

pedestal level and black level to be the same level.

P

edestal Lebel

Blac

k Lebel

1. Enter the service mode.

. Receive the 16-step grey scale computer signal with

computer1 [rGB]

mode.

3. To start the auto-calibration for PC adjustment, select

group no. “

260

”, item no. “

0

” and then change data

value from “

0

” to “

1

”. After the auto-calibration com-

pleted, "OK" will appear on the screen.

4. Auto calibration adjustment [Pc]

Below adjustments are performed when the above

auto calibration is failed.

Pedestal adjustment [component]

1. Enter the service mode.

. Receive the 16-step grey scale 480i-component signal

with

computer2 [component]

mode.

3. Connect an oscilloscope to test point “

tP35G

” (+)

and chassis ground (-).

4. Select group no. “

0

”, item no. “

0

” and change data

value to adjust the pedestal level and black level to be

the same level.

5. Connect an oscilloscope to test point “

tP35r

” (+)

and chassis ground (-).

6. Select item no. “

1

” and change data value to adjust

the pedestal level and black level to be the same lev-

el.

1. Enter the service mode.

. Receive the 8 color 100% color bar 480i-component

signal with

computer2 [component]

mode.

3. To start the auto-calibration for Component adjust-

ment, select group no. “

260

”, item no. “

0

” and then

change data value from “

0

” to “

1

”. After the auto-cali-

bration completed, "OK" will appear on the screen.

5. Auto calibration adjustment [component]

Below adjustments are performed when the above

auto calibration is failed.

7. Connect an oscilloscope to test point “

tP35B

” (+)

and chassis ground (-).

8. Select item no. “

2

” and change data value to adjust

the pedestal level and black level to be the same lev-

el.

P

edestal Lebel

Blac

k Lebel

Gain adjustment [component]

1. Enter the service mode.

. Receive the 16-step grey scale 480i-component signal

with

computer2 [component]

mode.

3. Connect an oscilloscope to test point “

tP35G

” (+)

and chassis ground (-).

4. Select group no. “

0

”, item no. “

3

” and adjust the ampli-

tude “

a

” to be minimum by changing the Data value.

(a)

White Level

Summary of Contents for PLC-XU301

Page 63: ... 63 IC Block Diagrams FA5550NG P F Control IC621 XR16L5701IL24 UART IC9885 ...

Page 67: ... 67 IC Block Diagrams MR4010 Power OSC IC631 PIC18F67J60 LAN CONTROL IC8801 ...

Page 68: ... 68 IC Block Diagrams FA7703 DC DC Converter IC7811 Sil9127 HDMI Receiver IC8001 ...

Page 95: ...KD5 XU30100 95 Mechanical Parts List ...

Page 96: ... KD5AC MAY 2009 DC 200 Printed in Japan SANYO Electric Co Ltd ...

Page 108: ...A10 SCH_KD5AC NO DATA ...

Page 112: ...A14 PCB_KD5AC NO DATA ...