79

TROUBLESHOOTING

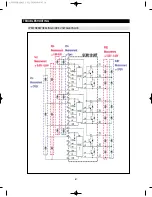

11) Ice Duct Heater(option) has trouble

1) Wire connector

2) Replace Heater

Is MAIN PCB

connector (CN51,CN79,CN76)

inserted correctly?

Is the input voltage of IC01

MICOM #50 normal?

Start

NO

YES

YES

YES

Bad contact of connector/ insert correctly

NO

1) Recheck the wire

2) Replace PCB MAIN

NO

Normal(recheck)

ERROR Code

☞

Checking method of Flex Room Damper

resistance CN51-"2"(Brown)

↔

CN79-"2"(Yellow)

**

∞Ω

: Open(wire disconnection, heater

disconnection) trouble / 0

Ω

: Short trouble

Start

YES

YES

YES

Is Tank Water Heater

normal?(about 60ohm)

Is Tank Water Heater

normal?(about72ohm)

Heater

Connector

ohm

Ice Duct

CN51-#2

↔

CN79-#2

60ohm

±

7%

Heater

Micom

(IC01)

Initial

power On

Heater

off

Working

heater

#50

3.5V ~

4.8V

3.5V ~

4.8V

0V

Ice Duct

AW3 SM-EN 2011.3.31 2:56 PM 페이지79 in

Summary of Contents for RF4287HARS

Page 17: ...18 PRODUCT SPECIFICATIONS 2 5 Dimensions of Refrigerator Inches AW3SM EN2011 3 312 52PM 18 in...

Page 86: ...87 TROUBLESHOOTING IPM FREEWHEELING DIODE VOLTAGE VALUE AW3SM EN2011 3 312 56PM 87 in...

Page 96: ...97 TROUBLESHOOTING SPM Internal DIODE Voltage AW3SM EN2011 3 312 56PM 97 in...

Page 98: ...99 TROUBLESHOOTING INVERTER PCB Circuit Diagram AW3SM EN2011 3 312 56PM 99 in...

Page 124: ...125 7 1 Model RFG295AA BETTER 7 WIRING DIAGRAM BLU BLU AW3SM EN2011 3 312 57PM 125 in...

Page 125: ...126 7 2 Model RF4287AA BEST 7 WIRING DIAGRAM AW3SM EN2011 3 312 57PM 126 in...

Page 126: ...127 7 3 Model RFG299AA 7 LCD 7 WIRING DIAGRAM BLU BLU AW3SM EN2011 3 312 57PM 127 in...

Page 127: ...128 7 4 Model RFG294AA SEARS 7 WIRING DIAGRAM AW3SM EN2011 3 312 57PM 128 in...

Page 129: ...130 8 SCHEMATIC DIAGRAM 8 1 2 INVERTER BLOCK RF4287 AW3SM EN2011 3 312 58PM 130 in...

Page 130: ...131 8 2 CIRCUIT DIAGRAM SCHEMATIC DIAGRAM 8 2 1 MAIN AW3SM EN2011 3 312 58PM 131 in...

Page 131: ...132 SCHEMATIC DIAGRAM 8 2 2 INVERTER AW3SM EN2011 3 312 58PM 132 in...