1

3

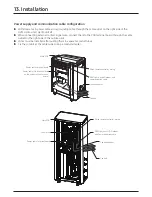

. Installation

Refrigerant pipe welding and safety information Important

information for refrigerant pipe work

•

Make sure there is no moisture inside the pipe.

•

Make sure there are no foreign substances and impurities in the pipe.

•

Make sure there is no leakage.

•

Make sure to follow the instruction when welding or storing the pipe.

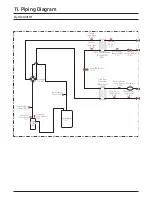

Nitrogen flushing while brazing (DVM Hydro unit)

•

When brazing the refrigerant pipes, flush them with nitrogen gas as shown in the picture.

•

If you do not perform nitrogen flushing when brazing the pipes, oxide may form inside the pipe and can cause damage to the

important parts such as compressor and valves etc.

•

Adjust the flow rate of the nitrogen flushing with a pressure regulator to maintain 0.05 m

3

/h (1.77 ft

3

/h) or less.

•

When brazing the pipes on the connection port, cover the valve with wet cloth before brazing (to protect the parts within the valve)

Brazed part

Nitrogen

Copper pipe [Φ6 .35 (1/4")]

Stop valve

Taping

High pressure hose

Nitrogen

Wet cloth

Gas side

(brazed)

Flowmeter

Φ 6 .35 (1/4")

Pressure regulator

Direction of the pipe when brazing

•

Direction of the pipe should be headed downward or sideways when brazing.

•

Avoid brazing the pipe with pipe direction heading upward.

Upward

Side

Downward