EB 8091-1 EN

23

Mounting and start-up

5 Mounting and start-up

SAMSON valves are delivered ready for

use. In special cases, the valve and actuator

are delivered separately and must be assem-

bled on site. The procedure to mount and

start up the valve are described in the follow-

ing.

Risk of valve damage due to excessively high

or low tightening torques.

Observe the specified torques on tightening

control valve components. Excessively tight

-

ened torques lead to parts wearing out

quicker. Parts that are too loose may cause

leakage.

Observe the specified tightening torques

(

u

AB 0100).

Risk of valve damage due to the use of un-

suitable tools.

Only use tools approved by SAMSON

(

u

AB 0100).

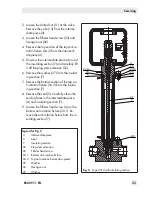

5.1 Mounting the actuator onto

the valve

Proceed as described in the actuator docu-

mentation if the valve and actuator have not

been assembled by SAMSON:

−

Remove the mounted actuator before

mounting the other actuator (see associat-

ed actuator documentation).

−

Preloading the actuator springs increases

the thrust of a pneumatic actuator and re-

duces the travel range of the actuator (see

associated actuator documentation).

5.2 Installing the valve into the

pipeline

5.2.1 Checking the installation

conditions

Pipeline routing

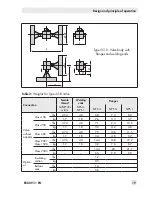

The inlet and outlet lengths vary depending

on the process medium. To ensure the control

valve functions properly, follow the installa-

tion instructions given below:

Î

Observe the inlet and outlet lengths (see

Table 3). Contact SAMSON if the valve

conditions or states of the medium pro-

cess deviate.

Î

Install the valve free of stress and with the

least amount of vibrations as possible. If

necessary, attach supports to the valve.

Î

Install the valve allowing sufficient space

to remove the actuator and valve or to

perform service and repair work on

them.

NOTICE

!

NOTICE

!

Note

Summary of Contents for 3510

Page 29: ...EB 8091 1 EN 29...