14

EB 8091-1 EN

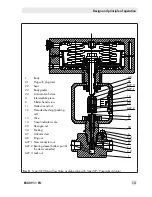

Design and principle of operation

3.2 Versions

The modular design allows an insulating sec-

tion or metal bellows to be fitted to the stan-

dard valve version.

If valve accessories (e.g. positioner, limit

switch etc.) are to be mounted to the valve

version with flanges, we recommend mount

-

ing an insulating section or bellows seal. This

provides more space to mount valve accesso-

ries.

Actuators

In these instructions, the preferable combina-

tion with a Type 3271 or Type 3277 Pneu-

matic Actuator is described. The pneumatic

actuator (with or without handwheel) can be

replaced by another pneumatic actuator in a

different size, but with the same travel.

Î

Observe the maximum permissible actu-

ator force.

If the travel range of the actuator is larger

than the travel range of the valve, the spring

assembly in the actuator must be preloaded

so that the travel ranges match. See associ-

ated actuator documentation.

The basic pneumatic actuator can be re-

placed by a pneumatic actuator with addi-

tional handwheel or by an electric actuator.

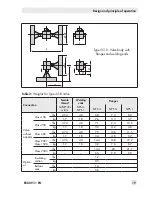

3.3 Technical data

The nameplates on the valve and actuator

provide information on the control valve ver-

sion. See section 2.1 and the actuator docu-

mentation.

More information is available in Data Sheet

u

T 8091-1.

Compliance

The Type 3510 Valve bears the EAC mark of

conformity:

Temperature range

Depending on the version, the control valve

is designed for a temperature range from 14

to 428 °F (–10 to +220 °C). The use of an

insulating section or bellows seal extends the

temperature range from –325 to +842 °F

(–196 to +450 °C). Special materials are

available for temperatures up to 1200 °F

(650 °C).

Leakage class

Depending on the version, the following

leakage class according to ANSI/FCI 70-2

or IEC 60534-4 applies:

−

Leakage class IV with metal seal

−

Leakage class V for high-performance

metal seal

Tip

Note

Note

Summary of Contents for 3510

Page 29: ...EB 8091 1 EN 29...