JOLLY

www.larius.com

29

REV.

01 - 09/2020 - Cod. 150165

T

V

Q

W

S

U

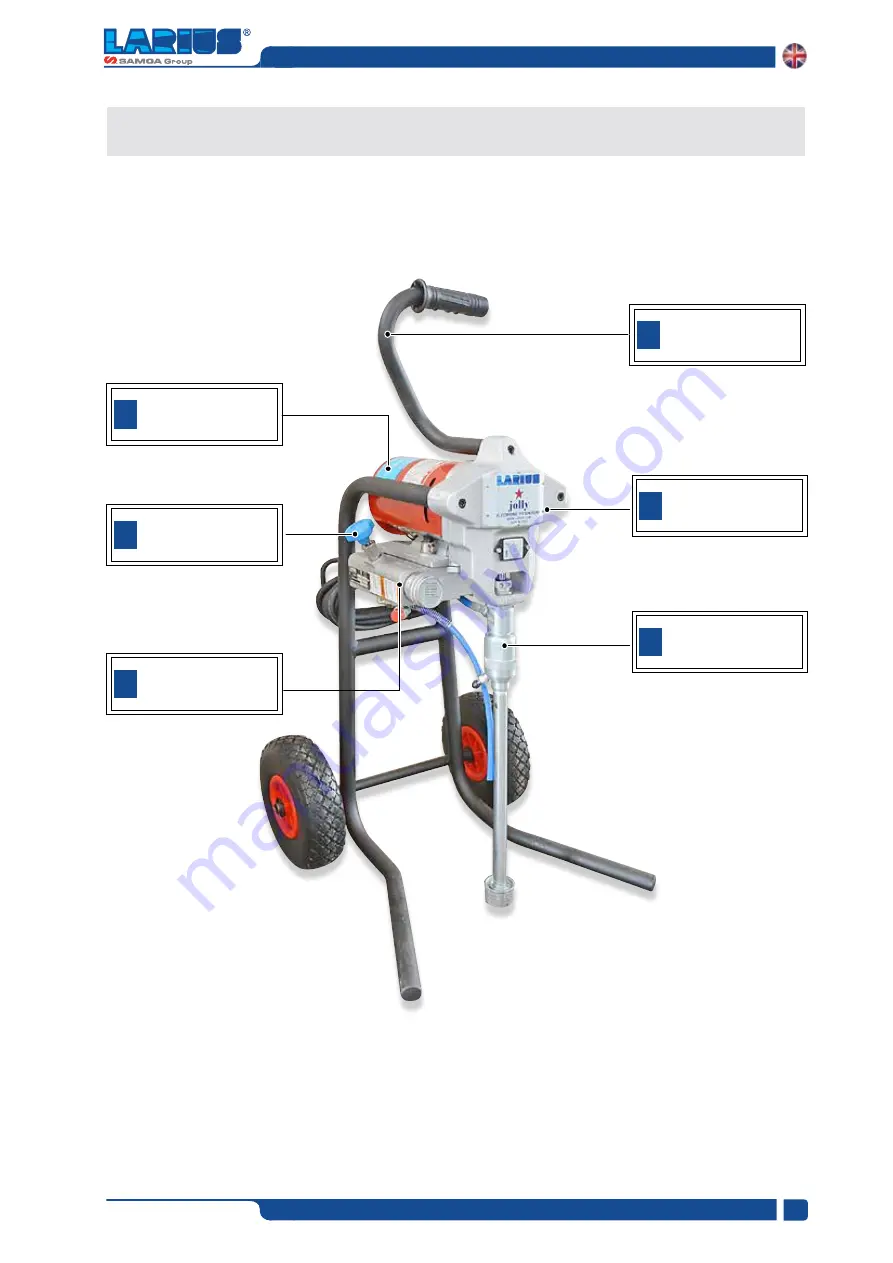

SPARE PARTS

version on trolley

Trolley

page 36

Complete electro-hydraulic

control device

page 38

Recirculating-safety valve

group

page 30

Electric motor

page 43

Complete electromechanical group

page 32

Complete hydraulic group

page 36