Instruction manual

Fodder wagons OptiFEED

6

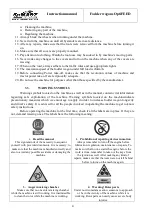

Make sure that the power take-off is connected properly. That means the shear pin has been

put on and restraining device has been mounted from both sides.

Power take-off has to be properly secured. If the cover is damaged it should be replaced

immediately.

Hydraulic hoses have to be checked before first use. Then they shall be subject to periodic

inspection once a year. If necessary, they have to be replaced. Working duration of

hydraulic hoses is 6 years, including up to 2 years of storage. Always replace hydraulic

hoses with those that fulfill manufacturer’s expectations. All hydraulic hoses are stamped

with date of production.

Before turning the hydraulic system on, make sure that the hydraulic clutch is connected and

the cords or juncture are not damaged.

After the engine is turned on, turn on tractor’s hydraulic valves to make sure that there is no

pressure in hydraulic hoses. Hydraulic fluid under pressure may penetrate the skin and cause

serious infection. Always protect the skin and eyes from hydraulic fluid. If you are hit by the

pressurized fluid, see the doctor immediately.

Before connecting hydraulic system make sure that the mixing rotor, unloading cover and

fodder feeder are not blocked.

Make sure that no one is near the machine while it is being turned on. If there is air in

hydraulic system, it may cause the machine to move unexpectedly.

4.2.

SECURING THE MACHINE

It is essential for the motor not to be overloaded. This is why the power take-off is secured

by a shear pin. Under no circumstances use pins of other dimensions or qualities than of those of the

type mounted. Never clean parts of weight control system or display with pressurized water. Do not

use large amounts of fodder from long straw. Always add it in low quantities. You should not use

more than 250kg of long straw fodder for one mixing process.

5.

THE CONSTRUCTION OF FODDER WAGON

Fodder wagon is equipped in electronic weighing machine which allows for precise

measurement of components from which the dose is made out of. Auger with blades guarantees

quick and total mixing of all fodder components. Ring preventing unloading, located on the top of

the container, prevents fodder from leaking out during mixing process.