11

4.2 - BEFORE YOUR FIRST BREW

Close the tap and riser pipe valve. Add about 5 litres of water to

the brew kettle.

• Check for any water leakage underneath the brew kettle or

around any of the fittings. If any water is found, check and

tighten fittings. Check that the gaskets are properly inserted.

Read instruction for pump maintenance (described later in

this user manual), and check silicone hose and fittings.

If there are no indications of any leakages, connect the lid hose

CamLock connector to the riser pipe, place the lid on top of the

boiler and connect the power cord to a wall outlet. The built-in

light in the brew program selector will now illuminate.

Switch the brew program selector to “

• • •

” and press “ON”

button on the brew controller. This will initiate heating of the

water to 100°C. Wait until the water is boiling, then open the

riser pipe valve before switching on the pump. Let the pump run

for about 10 minutes in order to clean the equipment pipes and

pump.

• While the pump is running you should check for leakages

around fittings and tighten the fittings if required.

Stop the pump and close the riser pipe valve. Disconnect the lid

hose and remove the lid. Attach the whirlpool pipe. Open the

valve and start the pump again. Let the pump run for another 5

minutes.

• Check for leakages around the whirlpool pipe fittings. Tighten

the fittings if required.

Connect hoses to the immersion cooler and connect one hose

end to a cold water tap. Place the other hose outlet in a drain

opening. Turn on the water.

• Check for leakages around the cooler pipe fittings. Tighten

the fittings if required.

Chapter 5

USING THE

BEER BREW

AUTOMATIC™

This chapter will explain brewing in general, and how to use

the brew controller and the program selector switch during

brewing.

5.1 -

ABOUT BREWING BEER

Brewing beer is all about converting the grain starches into

fermentable sugars. This user manual describes how to use

crushed malt (grain that has been malted, and then milled) as

the main ingredient to create a wort that is fermented, and

where the result is beer.

The brewing process mainly consist of three main phases:

Mashing,

i.e. converting the starches in the crushed malt to

fermentable sugar. This will create the sweet, sugary liquid that

is called wort. Mashing time is normally 60 minutes, although

some prefer to mash up to 90 minutes.

Lautering

can be divided into three different sub-processes:

Mashout (increase temperature in the mash to 78°C), to make

the wort and sugar more fluid. Circulation of the wort, i.e.

drawing water from the bottom of the mash, adding it to the top

and at the same time using the mash to filter the wort. This is

also called Vorlauf (German), where the circulation contributes

to filter the wort, making it clearer. Sparging is adding hot water

(about 78°C) to the mash, in order to extract the remaining

sugar from mash into the wort. Lautering time is normally

between 60 and 90 minutes, depending on the technique and

equipment setup.

Boiling

is done to allow the sulfur compounds in the wort to

evaporate, and also to achieve a hot break, causing the proteins

to coagulate. During the boiling period, the hops are added to

create the desired bitterness, hop flavour and aroma. Boiling

time is normally 60 minutes. If the malt grist contains pilsner

malt the boiling time should be 90 minutes.

After the boil, the wort is cooled down before transferring it to

a fermentation vessel and adding the yeast. Check your yeast

instruction to find pitching temperature (normally about 20°C)

and the optimal fermentation temperature.

When the fermentation is over the beer must be bottled or

kegged. Remember to add priming sugar (normally between 5

and 10 grams per litre of beer, depending on the beer style),

for carbonating the beer, i.e. adding CO2 into the beer. Sugar

can also be added when kegging, unless you chose to add

carbonation to the beer in the keg using an external CO2

source. After a period of storage in room temperature, normally

2 weeks, the added sugar is fermented by the remaining yeast,

resulting in CO2 in the beer. After this period, the beer should

be stored cold, until you chose to consume it.

A good source for reading more about beer brewing is the book

“How to brew”

by John Palmer. The 1st edition is available for free

at

http://www.howtobrew.com/

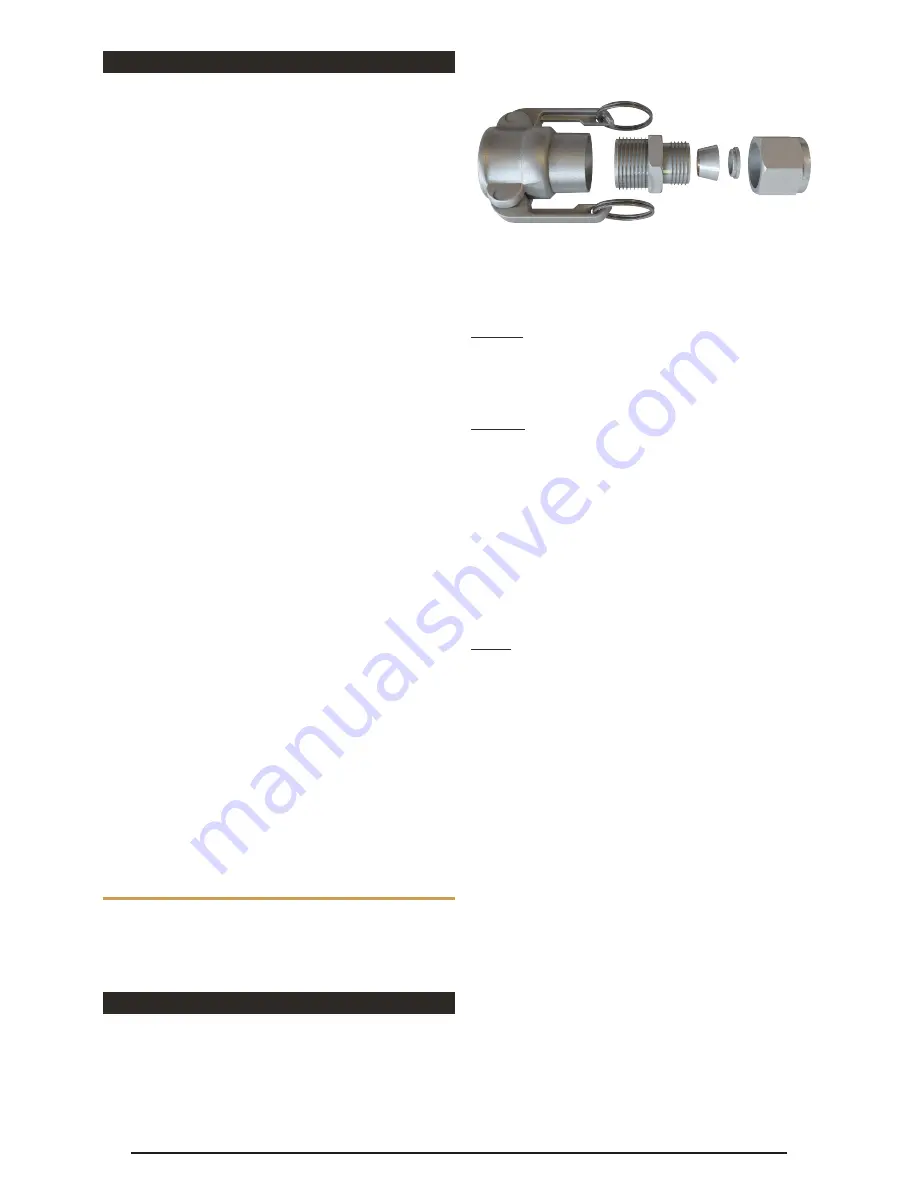

Fittings for the whirlpool pipe