9

TECHNICAL DATA

The values shown are based on a nominal voltage of 230V/50Hz. In the case of voltages and frequencies of different power values may vary.

Refer to the label technical specifications to the nominal values of the tool.

GENERAL WARNINGS

All instructions concerning safety and the prevention of industrial accidents

can be found in file SAFETY INSTRUCTIONS, that forms integral part of this

documentation. This INSTRUCTION MANUAL only contains additional

information that specifically explain how to use the machine.

SPECIFIC USE

General safety instructions

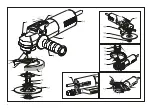

This electrical tool is designed to operate as a grinder, grinding and

abrasive cutting operations, metal brushing. Read all safety warnings,

instructions, illustrations and specifications supplied with this electrical

tool.

Failure to respect all instructions shown below may cause electric shock,

fire and/or serious accident.

Sanding and polishing operations are not recommended with this electrical

tool.

Operations for which the use of the electrical tool is not provided for can

create hazards and cause harm to personnel.

Theuse of this tool for smoothing, metal brushing and polishing operations

is not recommended.

Its use for applications other than those for which it has

been designed may lead to hazardous situations and cause injuries to people.

Do not use accessories that are not specifically designed for the intended

use of the tool or that have not been recommended by the manufacturer.

The fact that an accessory can be fixed to the tool does not imply that it can be

used safely.

The rated speed of accessories must be at least equivalent to the maximum

speed of the tool.

If operated at a greater speed than the rated one,

accessories may break and cause the ejection of chips.

The external diameter and thickness of accessories must be appropriate to

guarantee the protection and safety of the tool.

Accessories with incorrect

dimensions cannot be adequately protected or controlled.

The configuration of the cutting/grinding wheels or any other accessory

mustperfectly adapt to the tool spindle.

Accessories with holes that cannot be

aligned with the fitting components on the tools will cause unbalance, excessive

vibrations and may be difficult to control.

Do not use an accessory if damaged. Before use, inspect all the accessories,

like the abrasive cutting/grinding wheels, in order to verify that they are not

cracked or splintered. If the tool or accessory has fallen, verify that they are

not damaged and, if necessary, replace it with a new one. After inspecting

or installing an accessory, move to a safe distance with any other person

present and operate the tool at maximum speed without load for one minute.

Damaged accessories generally break during this test period.

Wear personal protective equipment. According to the the application, use

face shield, mask or safety goggles. According to the case, wear a dust

mask, ear protection, gloves and a smock capable of stopping small abrasive

fragments of the work piece.

Eye protection must be able to stop flying bits

produced from the different operations The dust mask or the respirator must be

capable of filtering particles produced by your work. Prolonged exposure to high

intensity noise can cause a loss of hearing.

Keep the people present at a safety distance with respect to the work area.

Anyone entering the work area must wear personal protection equipment.

The fragments of the work piece or the broken accessories can fly off and cause

injuries in the immediate vicinity of the work area.

Keep the tool only for isolating gripping surfaces, while the operations are

carried out in which the cutting accessory may be in contact with the hidden

cables or with its cable.

The contact between the cutting accessory and the

TYPE

BA31ES

PROTECTION CLASS

/ II

ABSORBED POWER W

900

ELECTRONIC OVERLOAD PROTECTION

YES

ELECTRONIC SPEED CONTROL

YES

n NOMINAL RPM /min

1.500 ÷ 4.000

Ø DISC PAD DIAMETER mm

115

SPINDLE THREAD

M14

DISC SPINDLE STOP

YES

EXTRACTION SYSTEM (*)

CENTRALIZED

WEIGHT kg according to EPTA-Procedure 01/2003

2,1

(*) The tool must be connected to a suitable dust extraction system (not supplied).

Summary of Contents for BA31ES

Page 2: ...2...

Page 34: ...34 230 50 EPTA 01 2003 BA31ES II 900 1 500 4 000 115 M 14 2 1...

Page 35: ...35...

Page 38: ......

Page 39: ......