12

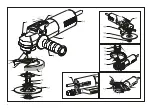

REPLACING THE ABRASIVE DISCS

This can be done in one of two ways:

1. Mode:

lock the wheel holder shaft (5) pushing button (4) simultaneously

rotating the abrasive disc holder sanding pad (12) until alerted of its

locking. Unlock the wheel spindle by releasing the buttonand rotate the

wheel by hand to ensure that it runsfreely. Release the wheel holder

shaft by releasing the button and manually rotating the abrasive disc

holder sanding pad to control its unlocking.

WARNING!: never press the wheel spindle locking button until

the tool has stopped moving and is perfectly stationary; the gear

box or the push button pin could be broken and the guarantee

would be invalidated.

2.Mode

insert the 17 mm wrench (13) into the pocket of the shaft between

the abrasive disc holder sanding pad and the gear box to lock the

wheel holder shaft (5). Proceed as in the 1st mode: “Unscrew the ring

nut [...]”

Tools other than those mentioned must not be used for slackening for

tightening purposes.

WARNING

: Before use, check the state of the wheel. The wheels

must be properly assembly and must rotate freely rotate freely.

Never use defective or damaged wheels/cutters. Defective

wheels can fall to pieces and cause dangerous incidents.

Start the tool and check that there are no unusual vibration, no dismatching

movement of the abrasive disc.

Otherwise switch-off the tool immediately and

eliminate the cause.

STARTING AND STOPPING

- Starting: push the slide of the ON/OFF (2) forward; if the tool is to be locked in

the ON position, apply pressure to the front part of the slide switch at the same

time.

- Stopping: release the slide ON/OFF (2).

If locked, press the ON/OFF switch in the lower part downwards and release it

in the OFF position.

WARNING

: after an interruption of the electrical energy, if the

ON/OFF switch is inserted, it is necessary to release the switch

(see Stopped).

ELECTRONIC RPM REGULATION

The rpm can be adjusted by rotating the speed adjustment wheel(3) located on

the rear of the tool. The choice of speed depends on the characteristics of the

abrasive paper disc and the material to be worked.

ACCESSORIES

Abrasive discs Ø 115 mm.

The use of tools of larger diameter will overload the motor and

drive system leading to rapid deterioration.

MAINTENANCE

All maintenance operations are carried out with the power supply

disconnected

. At the end of each work session, or when required,

remove any dust from the body of the tool using a jet of compressed

air, paying particular attention to the motor ventilation slots.

No other maintenance operations must be undertaken by the user.

Maintenance and cleaning of the inner parts, like brushes, ball bearings, gears

etc. or others, must be carried out only by an authorized customer-service

workshop or on www.rupes.com.

Use only the original RUPES parts or accessories.

DISPOSAL

For EC countries only

: According to the European Directive on Waste

from electrical and electronic equipment and its implementation in

conformity with national standards, exhausted electrical equipment

must be collected separately, in order to be recycled in an

environmentally friendly way. The product, when it reaches the end of

its life, must not be dispersed in the environment or thrown away as household

waste. It must be disposed at authorized recycling centres (contact your local

authorities to know where to dispose of the product according to the law). The

correct disposal of the product contributes to the health and preservation of the

environment.

Illegal disposal of the product will entail penalties against the offenders.

Disposing of the product correctly contributes to protecting human health and

safeguarding the environment. Any illegitimate disposal of the product will be

punishable by law.

We declare on our responsability that the hand-held motor operated tool, which

is mentioned in the present operating manual, is in comformity with the Essential

Requirements of Safety of the following Directives:

The tests have been carried out in accordance with following Standards:

IL PRESIDENTE

G. Valentini

S.p.A

CONFORMITY DECLARATION

Technical file at:

RUPES S.p.A.

Via Marconi, 3A

- Loc. Vermezzo

20080 VERMEZZO

CON ZELO

(Mi) - Italy

Vermezzo con Zelo

(MI),

22/05/2016

2006/42/EU; 2014/35/EU; 2014/30/EU; 2011/65/EU

EN 60745-1-2009 + A11:2010

EN 60745-2-3:2011 + A2:2013 + A11:2014 + A12:2014 + A13:2015

EN 55014-1:2006 + A1:2009 + A2:2011

EN 55014-2:1997 + A1:2001 + A2:2008

EN 61000-3-2:2006 + A1:2009 + A2:2009

EN 61000-3-3:2013

EN 62233: 2008

Summary of Contents for BA31ES

Page 2: ...2...

Page 34: ...34 230 50 EPTA 01 2003 BA31ES II 900 1 500 4 000 115 M 14 2 1...

Page 35: ...35...

Page 38: ......

Page 39: ......