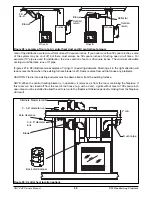

6. Slide the blower into place between the two brackets. You should be able to see the wheels of the blower.

7. Mount the thermal switch on its support as shown in (Figure 18). The thermal switch support is located just

beneath the bottom of the firebox on the right hand side leg. Push the clips on to the support as far as they will

go.

NOTE: One thermal switch is all that is required to operate the internal blower, the central heat blower, or both.

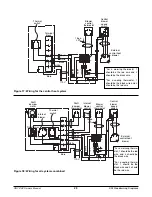

8. Locate the provided speed control in a switch box at a convenient location on the wall and connect it with

conventional 90° C 14-gauge wire (see Figure 17).

9. Replace the ash pan drawer and screw, the ash pan and the louver.

LOUVERS

The louvers above and below the door can be ordered in gold plate or black. You may order these from your

dealer.

FACING

Facing materials may only be non-combustible such as metal, brick, rock, concrete board, or ceramic tile. Gypsum

board is NOT an acceptable facing material.

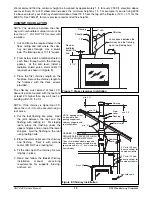

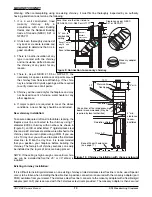

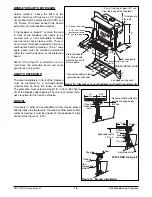

If you desire to fully face the fireplace with thin masonry, it is recommended that you purchase the rock retainer kit

(part FDKO). This kit is NOT recommended for brick or other self-supporting materials. Follow these steps and

refer to (Figures 19 & 20).

IMPORTANT: Make certain that the 1/4" space between the finishing trim and unit is sealed with silicone sealer

before installing the rock retainer kit.

WARNING: DO NOT RESTRICT AIRFLOW THROUGH THE INLET AND OUTLET LOUVERS OF THE

FIREPLACE.

NOTE: Remove the louvers and leave the door wrapped in the shipping plastic. Store them in a safe place until all

the masonry work is finished. Acid from the cleaning operation could permanently damage the gold plating.

INSTALLATION OF ROCK RETAINER KIT:

1. Install the heavy expanded metal on the face above and beside the door and louvers using drill-and-tap screws. There

are right and left side expanded

metal pieces. The expanded

metal is correctly installed

when the expanded metal is

facing upwards, to catch the

mortar (See Figure 19).

2. Cover the rest of the area

with wire mesh or metal lath,

overlapping the heavy

expanded metal. Make sure

nails or staples used for fas-

tening mesh penetrate studs

at least 1".

3. Mortar must be "thin set" or

"thin bed" type, inherently

polymer modified. Do not

add water to the mixture (this

applies to the grout as well).

If the mortar is not modified,

Figure 19: Installation of rock retainer (FDKO)

NOTE: Place

e x p a n d e d

metal, facing

upwards, to

hold mortar

Heavy expanded metal FDKO

9-#10 metal screws

Framing

Finishing trim /

stabilizing bracket

Metal

edging

ONYX AP Owner's Manual

RSF Woodburning Fireplaces

19