Page 9 of 16

①

. Move the flashing display to Zone

②

by pressing “MENU”, then press “RESET” to choose measurement

unit;

②

. Press “MENU” over 3 seconds to exit the setting mode.

B. Resetting the accumulated total

Press

“MENU” for 10 seconds, the accumulated total will be reset to be “0”.

C. Displaying current correction factor

Press “MENU” and “RESET” simultaneously and hold for 2 seconds. The display shows the correction factor.

(3) CALIBRATION PROCEDURE

A. Procedure for entering the correction factor directly

①.

Wait for the control valve to go to standby.

②.

Press the “MENU” key. Keep it pressed until the digit flashes in Zone

①

. Press the “RESET” key to

choose the right digit from 0 to 9. Press the “MENU” key to go the next digit so that the Actual Value can

be input.

③.

Make sure the correction factor is right and then press the “MENU” key. Keep it pressed until calibration is

finished and the factor is saved. The control valve will then return to standby.

B. Modify the correction factor in field

①.

Press the “RESET” for 1 second, Zone displays “0.00”.

②.

Start dispensing into a measuring glass.

③.

Stop dispensing when over 5 liters of volume is reached, then check the actual dispensed value. The

volume that is displayed on the LCD is the Display Value, not the Actual Value.

④.

Press the “MENU” key. Keep it pressed until the digit flashes in Zone

①

. Then press the RESET key to

choose the right digit from 0 to 9. Press the “MENU” key to go the next digit so that the Actual Value can

be input.

⑤.

Make sure the Actual Value is input right and then press the “MENU” key. Keep it pressed until calibration

is finished and the factor is saved. The meter will then return to standby.

(4) BATTERY REPLACEMENT

If Voltage is too low, low-power alarm device will be activated and light flashes in Zone

④.

When the LCD panel displays nothing or light flashes in Zone

④

, the battery should be replaced. Follow the

steps below to replace new battery.

①.

Open the battery cover (part# 3-11) with a flat screwdriver.

②.

Remove the old battery. Discard the battery in accordance with local laws and ordinances.

③.

Insert a 3.6V ER14250 battery into the battery compartment. Install the battery according to the direction

of polarity “+” & “-” indicated and insert the end of anode “+” first.

④.

Place back the battery cover (part# 3-11).

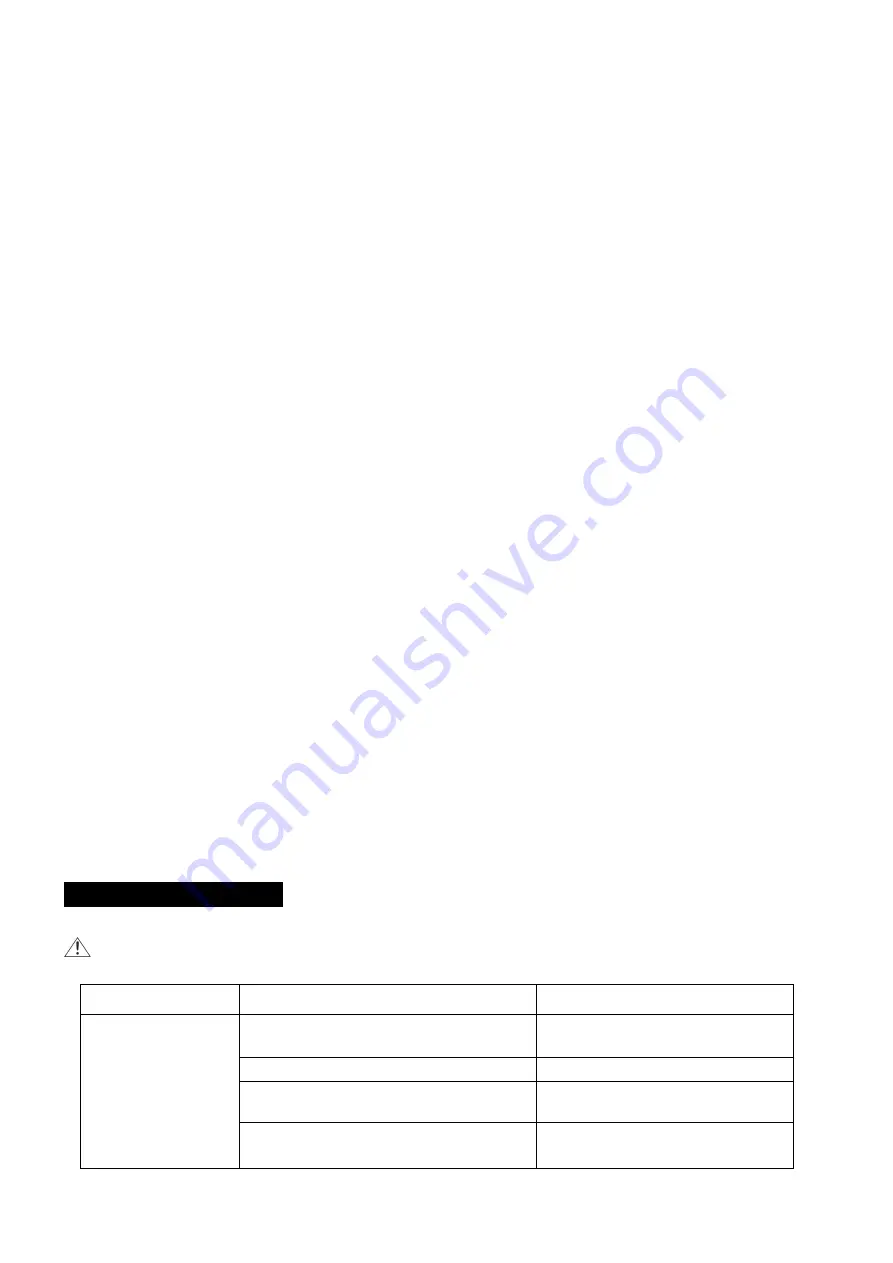

TROUBLE SHOOTING

WARNING: Relieve pressure before you check or service any system equipment.

Oil pump:

Problem

Possible Cause

Corrective Action

Inadequate air supply pressure or

restricted air lines

Increase air supply and/or

clear restriction

Closed or clogged control valves

Open and/or clean

Clogged fluid line, hose, valve, or

other accessory

Relieve pressure

Clear obstruction

Pumps fails to

operate

Damaged air motor

Assess damage, and service air

motor