4

Storage

Storage

If the actuators are scheduled for installation at a

later date:

a. The actuator should be placed in a clean and

dry place, and protected from the weather and

extreme vibration.

b. If actuator needs to be stored outside, it must

be protected from excess moisture, dust, and

weather.

Rotork cannot accept responsibility for deterioration

caused on-site once the covers are removed.

Every Rotork actuator has been fully tested before

leaving the factory to give years of trouble free

operation providing it is correctly commissioned,

installed and sealed.

Lubrication

The gear train has been lubricated during assembly

for the life of the actuator.

Installation

a. Before mounting actuator, verify that the

torque requirement is less than the output

torque of the actuator.

Mounting the actuator

The ROM actuator is suitable for quarter turn non

thrust applications. Ensure the valve is secure before

fitting the actuator, as the combination may be top

heavy and therefore unstable.

A suitable mounting flange conforming to ISO5211

or USA Standard MSS SP101 must be fitted to the

valve. Refer to label for conformation of output

flange details.

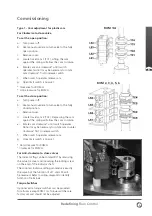

ROM can be supplied with adaptors to reduce

the size of the output drive square. The square

insert is fitted into the output drive. All ROM

actuators can be supplied with blank drive

bush. This is machined to suit the valve stem as

shown in the picture.

Actuator to valve fixing must conform to:

Material Specification ISO Class 8.8, yield strength

628 N/sq mm.

WARNING: Do not lift the actuator and

valve combination via the Actuator. Always lift

the valve/actuator assembly via the valve.

Before engagement, ensure that the actuator and

valve are in the same position (e.g. closed) and the

drive spline matches the stem position. Actuator

position can be determined using the local indicator

and if necessary can be moved using the manual

input drive. Secure the actuator with appropriate

fixing bolts. It may be necessary to adjust the

stop blots to enable sufficient travel. Ensure the

mounting bolts are tight.