d0

45

3

0

.f

m

MAINTENANCE MANUAL

BRP-Powertrain

Effectivity: 914 Series

Edition 2 / Rev. 0

12-20-00

page 21

January 01/2010

7) Locking the crankshaft

General note

.

NOTES:

The thread bolt for crankshaft locking is part of the stan-

dard tool kit supplied with each engine.

Locking the

crankshaft

The following work procedures are to be accomplished:

Loosen the

crankshaft

After completion of work/check:

WARNUNG

WARNING

Risk of Burns!

Hot engine parts!

Always allow engine to cool down to ambient tempera-

ture before start any work.

Step

Procedure

1

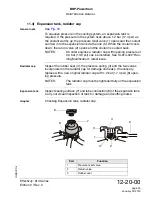

Remove the plug screw (1) M8x20 and sealing ring from the crankcase half

(cyl. 2/4).

2

Turn crankshaft/propeller shaft until the piston of cyl. no. 1 and no. 2 are in

TDC position and lock crankshaft in this position with the thread bolt (2)

part no. 240880.

NOTES:

Turn crankshaft for relief the position indification until the trig-

ger boss (3) is between the both trigger coil (4,5) at the po-

sition.

The required recess position of the crankshaft can be addi-

tionally verified by looking through the crankcase recess (6)

with a flash light.

3

Screw the thread bolt (2) into the crankcase. While doing so, move the crank-

shaft to and fro slightly with the ring spanner until the locking screw engages

in the recess (6) of the crankshaft, and tighten to 10 Nm (88.48 in.lb).

Step

Procedure

1

Remove the thread bolt (2) and refit crankshaft plug screw M8x20 (1) along

with a new sealing ring with a torque of 15 Nm (133 in.lb).

2

To check, use wrench 24 mm (15/16 inch.) to rotate the crankshaft at hex.

screw (7) on the magneto side.

Summary of Contents for 914 series

Page 183: ......