14

7. If the sheet was not cut correctly in steps 1 through 6 of the cutting test, change the cutting conditions.

• Changing the Pen Force

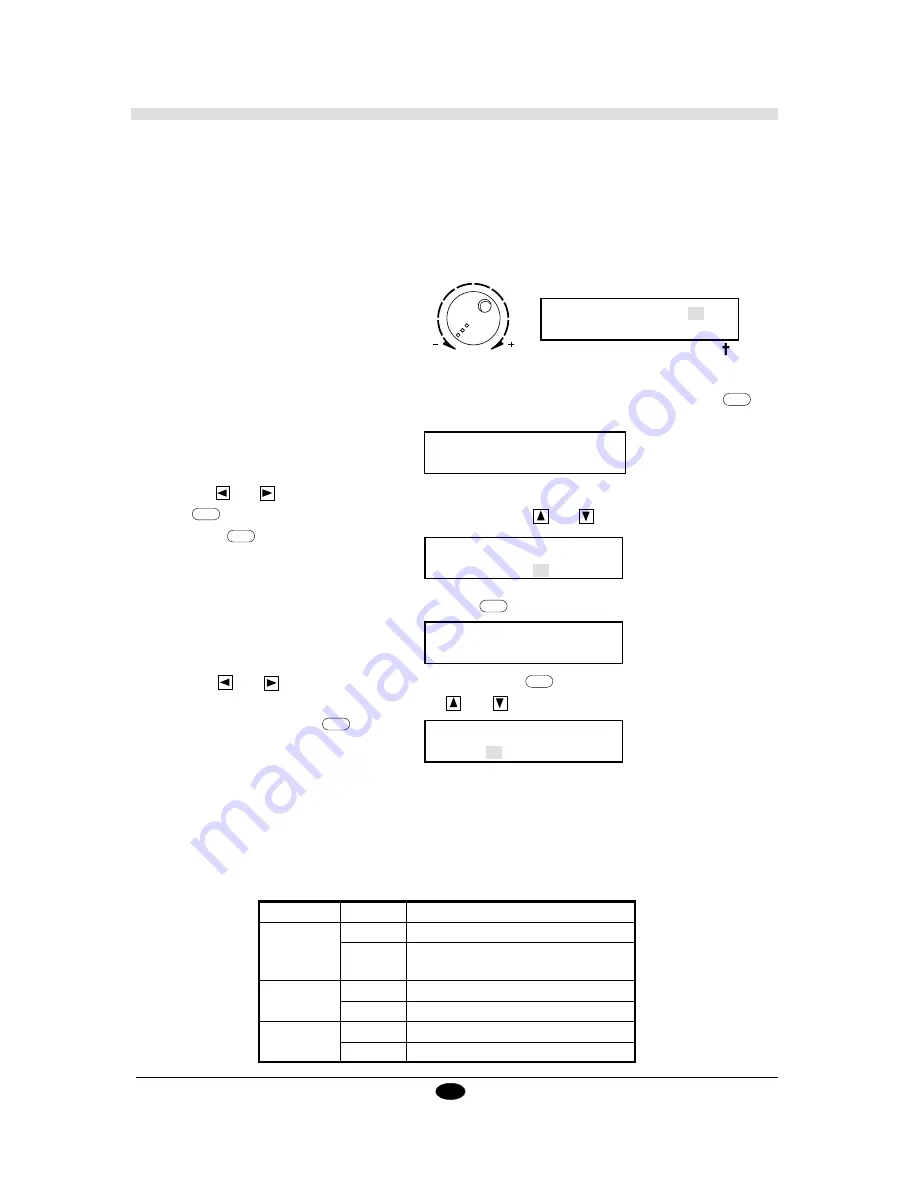

Use the pen force control on the top of the unit to adjust pen force knob to the appropriate setting. When

the pen force control is rotated all the way counterclockwise, the tool pressure is 30 g (minimum setting).

Pen force increases as the control is rotated clockwise, to a maximum of 200 g. During the cutting test,

Pen force is indicated in the upper right area of the display screen. Use this display when adjusting pen

force.

TEST CUT

30g

1:

●

2:

■

3:

• Changing the Speed

1. Speed can be changed either in the setup mode or in the cutting mode. This explanation describes how

to change speed when in the cutting mode. When the cutting test screen is displayed, press the

MENU

key

three times to display the following message.

2. Use the

and

keys to select first [TOOL,] then [CUTTER,] and enable these selections by pressing

the

ENTER

key. When the following message appears, use the

and

keys to change the speed, then

press the

ENTER

key.

SELECT HIT"ENTER"

TOOL FONT PEN-CHANGE

• Changing the Offset

1. While the cutting test screen is displayed, press the

MENU

key seven times.

2. Use the

and

keys to select [OFFSET,] and press the

ENTER

key to enable the selection.

When the following message appears, use the

and

keys to change the offset value, and enable

the selection by pressing

ENTER

key.

SELECT COMPENSATION

OFFSET SMOOTHING

SET OFFSET VALUE

10

8. One offset unit is equal to 0.025 mm. This means that the offset value in the procedure described above

is 0.25 mm. Whenever the cutting conditions have been modified, it is recommended that you once again

perform a cut test to confirm correct positioning and orientation.

The Chart below describes symptoms that occur when cutting conditions are not optimal. Use this chart for

comparison with the results of the cutting test .

S e t t i n g

Condition

Cutting result

Force

Too small

Some parts of the sheet remain uncut

Too large

The base paper is cut, and the cutter requires

frequency replacement

Speed

Too fast

Some parts of the sheet remain uncut

Too slow

Operating efficiency is reduced.

Offset

Too small

Corners are rounded

Too large

Corners flare outward, with "horns"

0

PEN FORCE

SETSPEED

CUTTER 20 cm/s

Summary of Contents for Sign Maker CAMM-1 PNC-1050

Page 1: ...ROLAND DG CORPORATION Model PNC 1050 User s Manual SIGN MAKER...

Page 41: ...39...

Page 42: ...F2082693BE V3 1...