39

6.16.3 Sump Breather

Inspect the sump breather element monthly. If the element is saturated it should be

replaced. A small amount of oil may be present in the housing outside the filter element;

this is normal and will drain back to the sump.

6.16.4 Control Air Filter

Inspect element monthly. Replace annually, or if saturated with condensate.

6.16.5 Engine Oil Filter

Similar in design to the Compressor Oil Filter, this filter should be changed with the

engine oil every 500 hours of service.

6.16.6 DEF Manifold Filter

A filter located inside of the DEF tank at the suction port of the pump.

6.16.7 Diesel Exhaust Fluid Filter

A secondary filter located on the exhaust aftertreatment system.

6.16.8 Fumes Disposal Filter Element

The filter for the open crankcase ventilation system (OCV) may be located toward the

front or toward the rear of the left side of the engine. A filter that has been used may

contain a small amount of engine oil.

6.16.9 Fuel System Primary/Secondary Filter (Water Separator) Element

Water in the fuel can cause the engine to run rough. Water in the fuel may cause an

electronic unit injector to fail. If the fuel has been contaminated with water, the element

should be changed before the regularly scheduled interval. The primary filter/water

separator also provides filtration in order to help extend the life of the secondary fuel

filter. The element should be changed regularly. The primary filter/water separator

should be changed at 50 to 70 kPa (15 to 20 inches Hg).

7. Standby and Stored Units

7.1. Standby Units

Back-up or stand-by compressors must be run weekly to assure that no condensation is

allowed to accumulate internally. When operated, a stand-by unit should be allowed to

reach full operating temperature for 30 minutes.

7.2. Short-term Storage

For storage intervals of one month or less, open the manual drains on the bottom of

automatic drain traps and run the unit fully loaded for 15 minutes. Drain water from the

Diesel fuel/water separator. In colder conditions approaching freezing temperatures, the

external connections for the heat trace and battery charger must be plugged in to an

120VAC external power source.

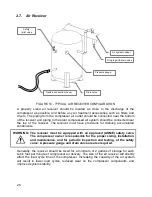

See FIGURE 6A/6B

for location of connections.