23

2. Installation

2.1. Inspection

Immediately upon receipt, the compressor should be inspected for damage. If any

damage is found, claims should be made against the carrier.

2.2. Handling

FIGURE 11 - FORKLIFT HANDLING

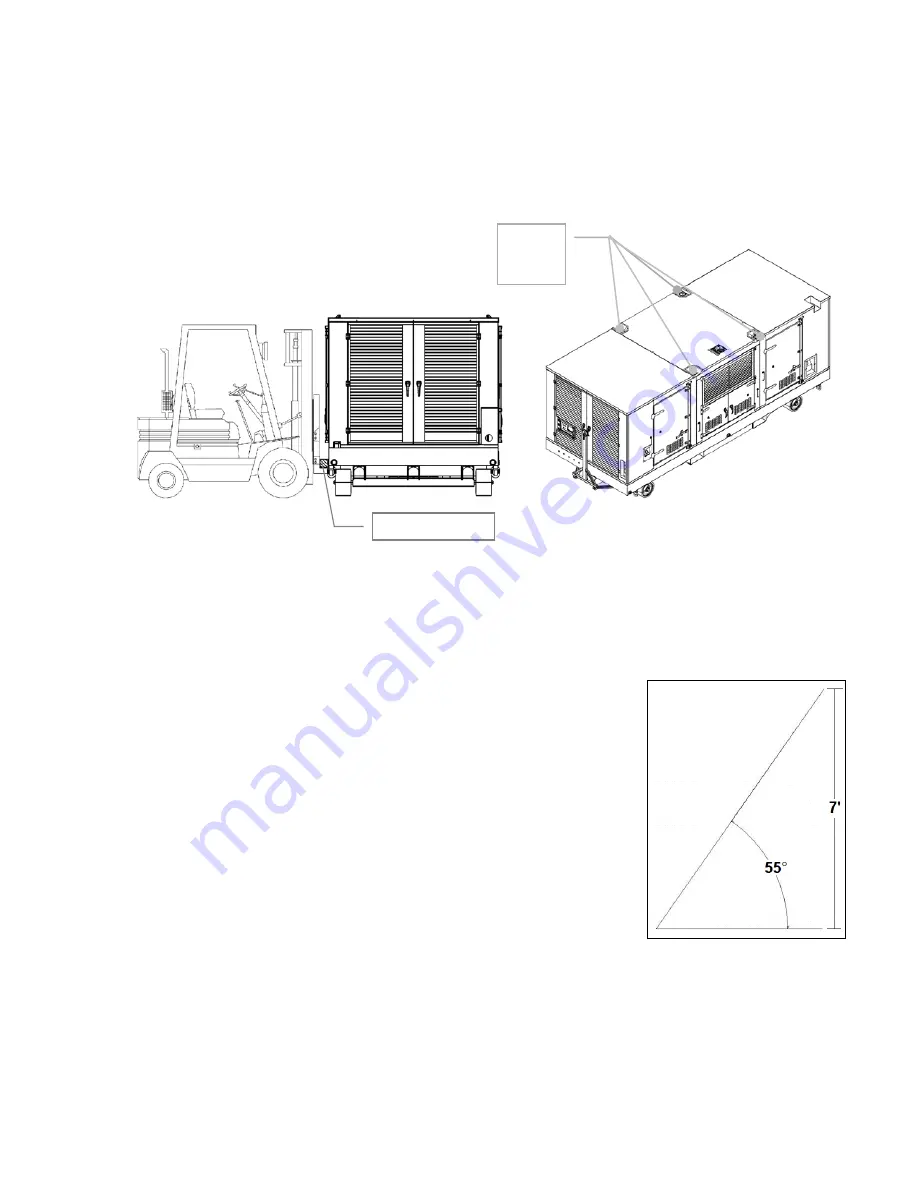

FIGURE 12 - CRANE HANDLING

The compressor unit is equipped with forklift slots for ease in handling. Spacer blocks

should be placed between the compressor and forklift mast to ensure the cabinet will not

be damaged during handling.

When handling the unit with an overhead crane, the lifting

straps or chains should attach to the integral lifting eyes.

There is an internal frame connected to the base, allowing for

overhead lifting, while also allowing for roof removal as

needed. Spacers and spreader bars should be utilized as

needed to avoid damage to the compressor cabinet. The

maximum allowable angle for lifting straps or chains is 55

degrees from horizontal, as shown in the diagram to the right.

That equals roughly seven feet of vertical height from the

bottom of the hook.

2.3. Foundation

The compressor should be mounted on a flat, level floor capable of supporting its full

weight. D-Rings are provided in the base on each corner for securing the compressor to

the mounting surface. The compressor air end / engine assembly is vibration isolated

from the cabinet, frame, and base. Additional isolation is not required.

Spacer blocks

Lifting

Frame

Eyelet