26

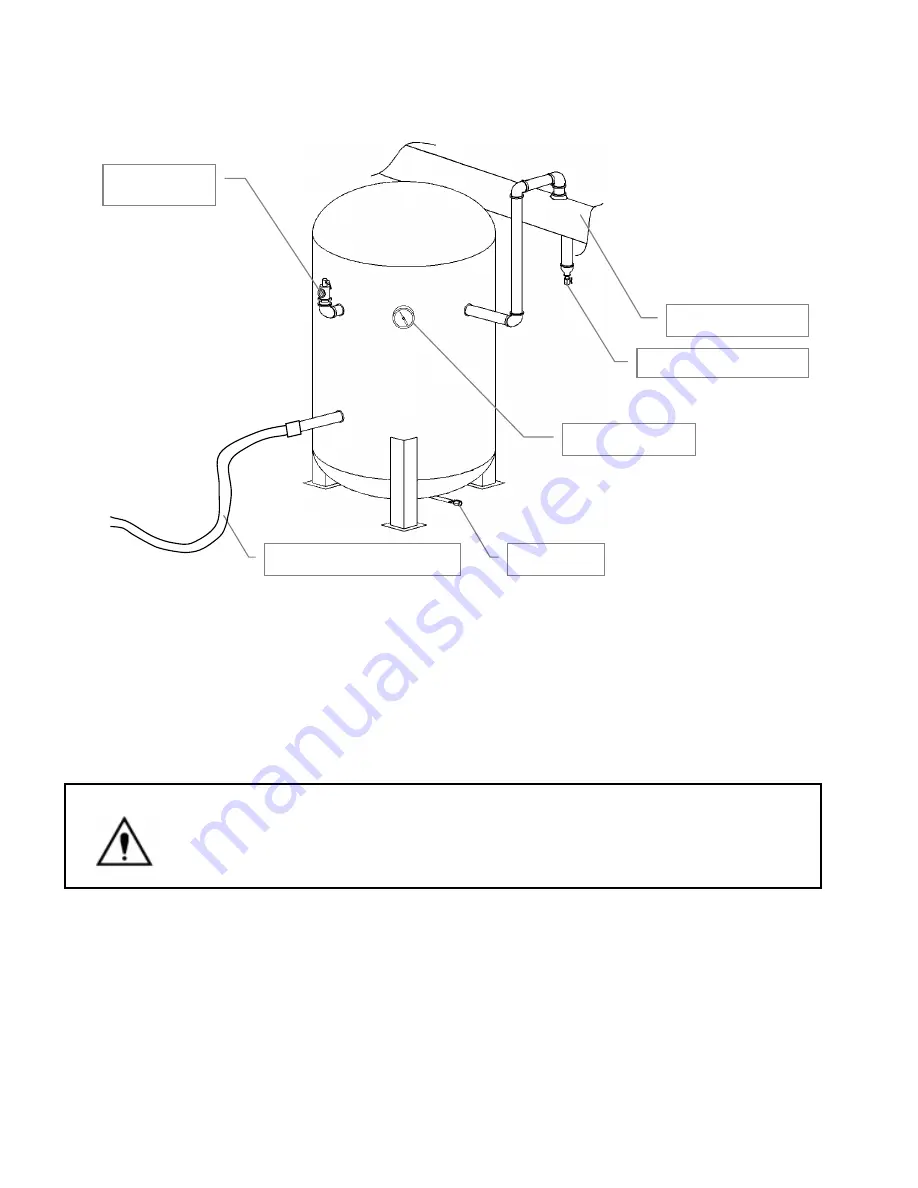

2.7. Air Receiver

FIGURE 13 - TYPICAL AIR RECEIVER CONFIGURATION

A properly sized air receiver should be located as close to the discharge of the

compressor as possible, and before any air treatment accessories such as filters and

dryers. The piping from the compressor air outlet should be connected near the bottom

of the receiver and piping to the plant compressed air system should be connected near

the top of the receiver. The receiver must have provisions for draining accumulated

condensate.

WARNING:

The receiver must be equipped with an approved (ASME) safety valve.

The compressor owner is responsible for the proper sizing, installation,

and maintenance, and for periodic inspection and testing, of the safety

valve. A pressure gauge and drain valve are also required.

Generally, the receiver should be sized for a minimum of 2 gallons of storage for each

cubic foot per minute of compressor air delivery. The size of the air receiver will directly

affect the load cycle time of the compressor. Increasing the capacity of the air system

will result in fewer load cycles, reduced wear on the compressor components, and

improved system stability.

Flexible connection (hose)

Safety

relief valve

Drain valve

Pressure gauge

Drop leg with drain valve

Air system header