33

•

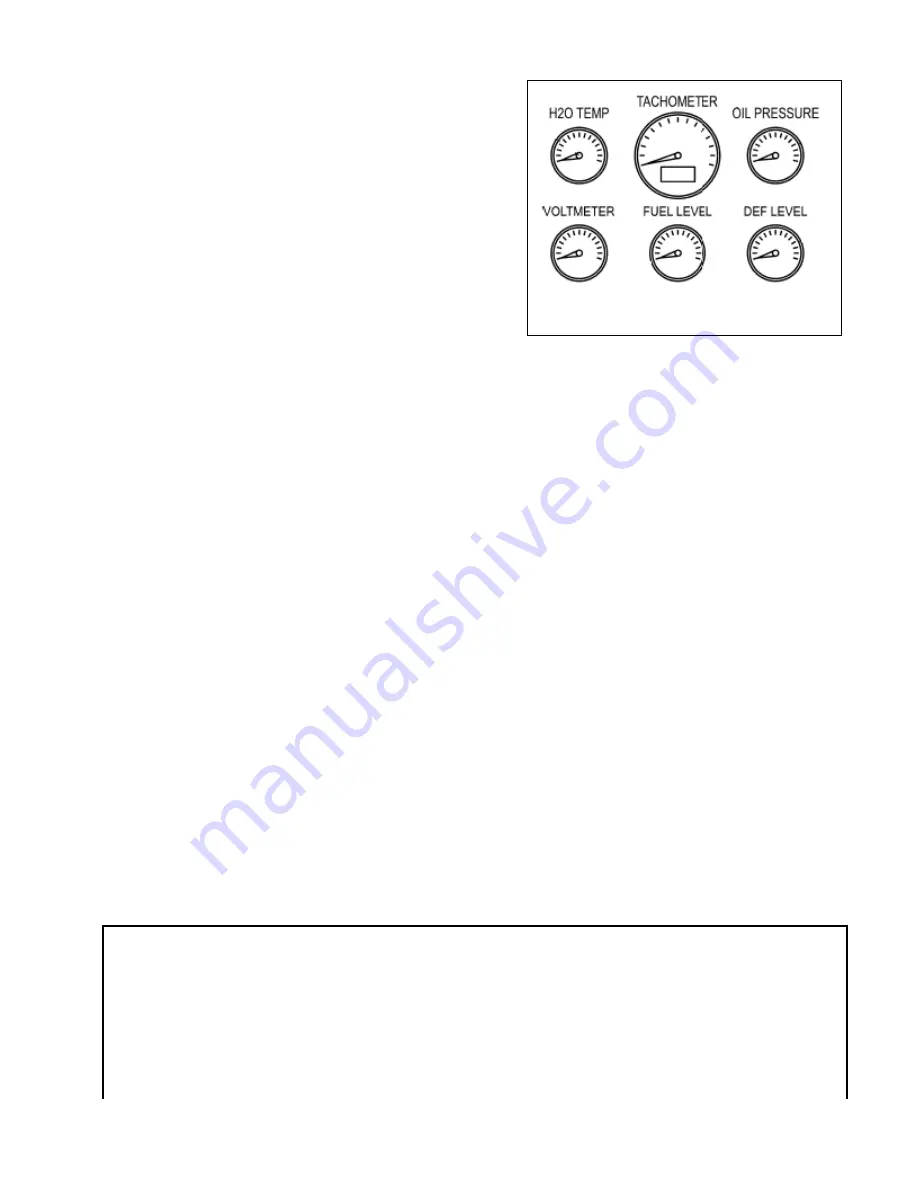

H2O Temp

: Displays the coolant

temperature of the engine.

•

Tachometer

: Displays rotation per minute

of the Diesel engine.

•

Pressure gauge marked "

Oil Pressure

":

Shows lubricant pressure at the Diesel

engine.

•

Fuel Level

: Shows the level of fuel in the

internal fuel tank. If an external fuel tank is

connected, the fuel level is not shown.

•

DEF Level

: Shows the level of Diesel

Exhaust Fluid in the internal DEF tank. If an

external DEF tank is connected, the fluid level is not shown.

A USB port extension on the front of the control panel and an SD card slot on the back

of the HMI are provided download trend data and alarm history from the standard HMI.

5.1.1 HMI Maintenance

The HMI uses an LCD (liquid crystal display) with LED backlighting. LCD’s are sensitive

to heat and direct sunlight. Maximum ambient temperature is 120

°

F (50

°

C). The

compressor is weather-resistant; however, care should be taken that direct sunlight does

not shine on the HMI. The touchscreen is a polyester film and is sensitive to abrasion.

Do not wear gloves when operating and do not press on the screen with hard or sharp

objects. A replaceable screen overlay is available to extend the service life of the

touchscreen.

Use only a clean soft cloth and mild detergent to clean the screen

.

If the HMI requires replacement, disconnect the communication cable, the 24VDC power

connector and the grounding wire. Use a Phillips screwdriver to remove the four

mounting clips.

5.2. Programmable Logic Controller

A programmable logic controller (PLC) is used to monitor and control compressor

operations. The PLC includes digital inputs and outputs to monitor compressor

conditions and control the starter and solenoid valves.

The Allen-Bradley CompactLogix 5069-L306ER is the PLC used for the GPKD-1550-H

compressors. Consult your local distributor for more information.

6. Maintenance

NOTICE:

The CAT C15 and C18 Diesel engine and its components require maintenance

at least every 250 operational hours and are generalized for this manual.

See the CAT Operations and Maintenance Manual SEBU9106-14 for

instructions.

Ensure that all safety information, warnings, and instructions are read and

understood before any operation or any maintenance procedures are

performed. The user is responsible for the performance of maintenance,

including all adjustments, the use of proper lubricants, fluids, and filters. The

FIGURE 14 – AUX. GAUGES