First start-up

32

5

For propane gas appliances, follow the same instructions

as given for natural gas. The manifold pressure for pro-

pane gas should be 5.1 inch WC and adjustment is made

at the gas valve regulator. Manifold pressure at 95.500

Btu/hr input using 0.14” nozzle.

The following Table 5.2

p. 32 summarizes nozzles and mani-

fold pressures for different types of gases.

Table 5.2

Manifold pressure and nozzle diameter

Gas type

natural gas

LPG

Manifold pressure

2.77 inch WC

5.1 inch WC

Nozzle diameter

0.21”

0.14”

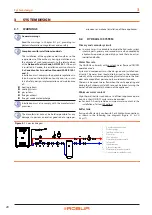

Gas pressure adjustment procedure (Figure

5.1

1.

Turn main gas valve knob to the "OFF" position.

2.

Remove the plug on outlet end of gas valve and attach

pressure tap and manometer.

3.

Switch on the appliance and close control switch.

4.

Wait for the burner to start up. Due to the presence of

air inside the piping, it may be that the burner does not

start at the first three attempts and, failing to do so, the

ignition system is locked out. If this happens reset the

p. 38). Repeat until all the

air is purged from the piping and the burner ignites.

5.

When the burner ignites read the manometer and

compare the value to the required pressure (Table

6.

If necessary change the manifold pressure using the gas

valve regulator. The regulator is built into the gas valve.

Remove the seal screw and turn adjusting screw clock-

wise to increase pressure or counterclockwise to reduce

pressure. Replace seal screw after adjustment.

7.

Open control switch and make sure that the appliance

is off.

8.

Remove manometer and pressure tap. Replace plug in

gas valve.

9.

Turn on the appliance by closing control switch. Check

all gas connections with soap for leaks.

Figure 5.1

Gas valve

INLET

PRESSURE

TAP

PRESSURE

REGULATOR

ADJUSTMENT

REMOVE CAP SCREW FOR

PRESSURE ADJUSTMENT

OUTLET

PRESSURE

TAP

INLET

OUTLET

OFF

ON

GAS CONTROL

KNOB

5.5

GAS CHANGEOVER

Only an authorised technician can perform the gas

change operation.

If the type of gas indicated does not correspond to the type to

be used (natural or propane gas) by the appliance, it must be

converted and adapted to the type of gas to be used.

The gas nozzle must be changed (Table 5.2

valve must be converted.

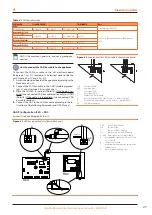

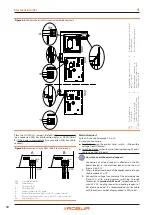

Gas change procedure (Figure 5.3

1.

Cut off electric power and gas supply.

2.

Remove front and left panel.

3.

Remove the wires from the gas valve.

4.

Remove the ring nut (H) from the threaded gas nozzle (C).

5.

Remove the gas nozzle (C) from the gas valve (A) by remov-

ing the 4 screws (G) from the valve flange (use 9/64" hex key

wrench). Put the o-ring (D) in a safe place, to be re-used with

the new nozzle.

6.

Attach the new gas nozzle to the gas valve using the 4

screws to secure valve flange: be sure to put the o-ring in

the proper site.

7.

Tighten the ring nut and re-attach wires to the valve.

8.

Restore the gas and electrical supply.

9.

Adjust the gas pressure for the gas to be used following the

instructions reported in Paragraph 5.4

10.

Replace the sticker indicating the type of gas for which the

unit is preset with the new one, which indicates the type ac-

tually being used.

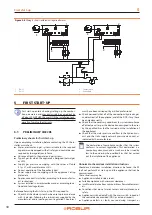

Figure 5.2

Gas valve

1

gas valve

1

Summary of Contents for GAHP-AR

Page 43: ......