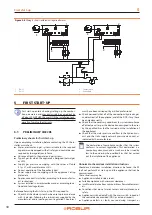

System design

20

3

3

SYSTEM DESIGN

3.1

WARNINGS

General warnings

Read the warnings in Chapter III.1

p. 4, providing im-

portant information on regulations and on safety.

Compliance with installation standards

The installation of the appliance must conform to the

requirements of the authority having jurisdiction or, in

the absence of such requirements, to the latest edition

of the

National Fuel Gas Code, ANSI Z223.1

. If the unit

is installed in Canada, the installation must conform to

the

Canadian Gas Association Standard CAN1 B149.1

and .2

.

Installation must comply with applicable regulations in

force, based on the installation Country and site, in mat-

ters of safety, design, implementation and maintenance

of:

heating systems

cooling systems

gas systems

flue gas exhaust

flue gas condensate discharge

Installation must also comply with the manufacturer's

provisions.

The manufacturer cannot be held responsible for any

damages to persons, animals or goods due to improper,

erroneous or irrational installation of these appliances.

3.2

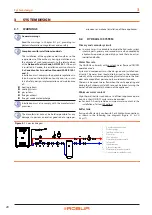

HYDRAULIC SYSTEM

Primary and secondary circuit

▶

In many cases it is advisable to divide the hydraulic system

into two parts, primary and secondary circuit, uncoupled by

a hydraulic separator, or possibly by a tank that also acts as

inertial tank/buffer.

Water flow rate

The GAHP-AR unit works with constant, water flow and ON/OFF

operative mode.

System and components must be designed and installed con-

sistently. The water lines should also be sized so the maximum

velocity of the water/monoethylene glycol solution in the lines

does not exceed 6 feet per second to avoid excessive noise.

There must be correct water flow when the unit is operating and

during the shutdown cycle (600 seconds, between turning the

burner off and complete shutdown of the appliance).

Minimum water content

High thermal inertia is conducive to efficient appliance opera-

tion. Very short ON/OFF cycles are to be avoided.

▶

For each GA unit provide a minimum water content in the

installation of at least 20 gallons.

Buffer tank

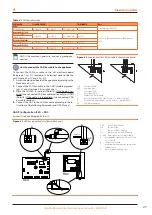

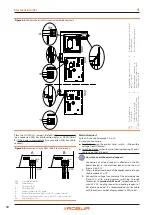

If using a buffer tank, it can be with 2 or 4 hydraulic connections,

as shown in the following two diagrams (Figure 3.1

3.2

Figure 3.1

2-pipe tank diagram

1

Anti-vibration connection

2

Pressure gauge

3

Inlet flow control device

4

Water filter

5

Shut-off valves

6

Water pump (primary circuit)

7

Safety valve

8

Expansion tank

9

Hydraulic separator

10 Water pump (secondary circuit)

11 2-connection inertial buffer tank

Summary of Contents for GAHP-AR

Page 43: ......