SPIROR HP - DR

Phase 4

‒

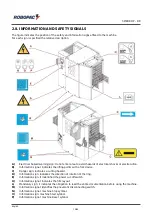

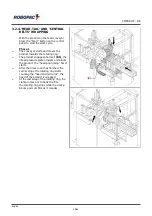

After the counting of the “head and tail

round” the rotating ring stops while the

gripper blocks the film and the arm with

the blade makes the cut.

‒

The outfeed conveyor restarts.

‒

The product detects the photocell

(B2)

,

timer begins counting the “conveyor

outfeed”.

‒

When timer has finished counting, the

conveyor stops and the products totally

wrapped can be removed from the

machine.

English

25/95

Summary of Contents for SPIROR DR

Page 16: ...SPIROR HP DR SPIROR HP SPIROR HP 300 SPIROR HP 400 600 English 16 95 ...

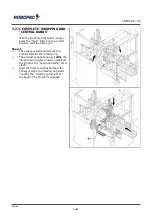

Page 17: ...SPIROR HP DR SPIROR HP 900 SPIROR DR SPIROR DR 400 600 Optional English 17 95 ...

Page 18: ...SPIROR HP DR SPIROR DR 400 600 SPIROR DR 900 Optional SPIROR DR 900 English 18 95 ...

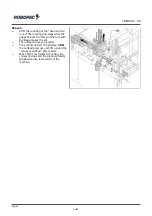

Page 38: ...SPIROR HP DR SPIROR HP 600 SPIROR HP 900 English 38 95 ...

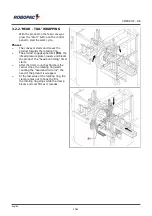

Page 39: ...SPIROR HP DR SPIROR DR 400 SPIROR DR 600 English 39 95 ...