SPIROR HP - DR

―

All safety devices must be integral and efficient.

―

The machine must be cleaned and in order.

―

Compressed air supply must be open and pressure adjusted to

6 bar

.

―

The film reel must be sufficiently full to guarantee operations (See "Coil replacement").

―

The film must not be blocked in the clamp (See "Inserting the film into the gripper").

―

The rotating ring must be in phase (see “Timing of the rotating ring”).

―

Turn main switch in pos.

"I"

.

―

Follow the indications displayed.

When the main page is displayed, the machine is ready to perform the operation after pressing the Start

button (See “Commands description”).

|

Note

At first start up after a change of operation, it is necessary to perform some trial cycles to check the quality of

the wrapping operation.

6.9.1.PUTTING THE ROTATING RING IN PHASE

The machine does not operate and does not block the film in the clamp if the rotating ring is not

in phase.

With the rotating ring in any position, pressing the Reset button will align the ring instead of starting the

operation.

Work can then be started.

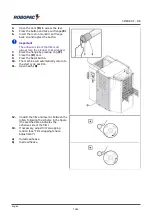

6.9.2.FILM SPOOL LOADING

For any model

1.

Display the main page.

Touch the key

(A)

to access the manual

movements (see section “Description of

the operating terminal” - “Description of

manual controls”).

2.

Touch the wheel

(B)

key to enable it and

then the "reel" key

(C)

.

The reel unit will move in front of the

door

(D)

automatically.

English

72/95

Summary of Contents for SPIROR DR

Page 16: ...SPIROR HP DR SPIROR HP SPIROR HP 300 SPIROR HP 400 600 English 16 95 ...

Page 17: ...SPIROR HP DR SPIROR HP 900 SPIROR DR SPIROR DR 400 600 Optional English 17 95 ...

Page 18: ...SPIROR HP DR SPIROR DR 400 600 SPIROR DR 900 Optional SPIROR DR 900 English 18 95 ...

Page 38: ...SPIROR HP DR SPIROR HP 600 SPIROR HP 900 English 38 95 ...

Page 39: ...SPIROR HP DR SPIROR DR 400 SPIROR DR 600 English 39 95 ...