10

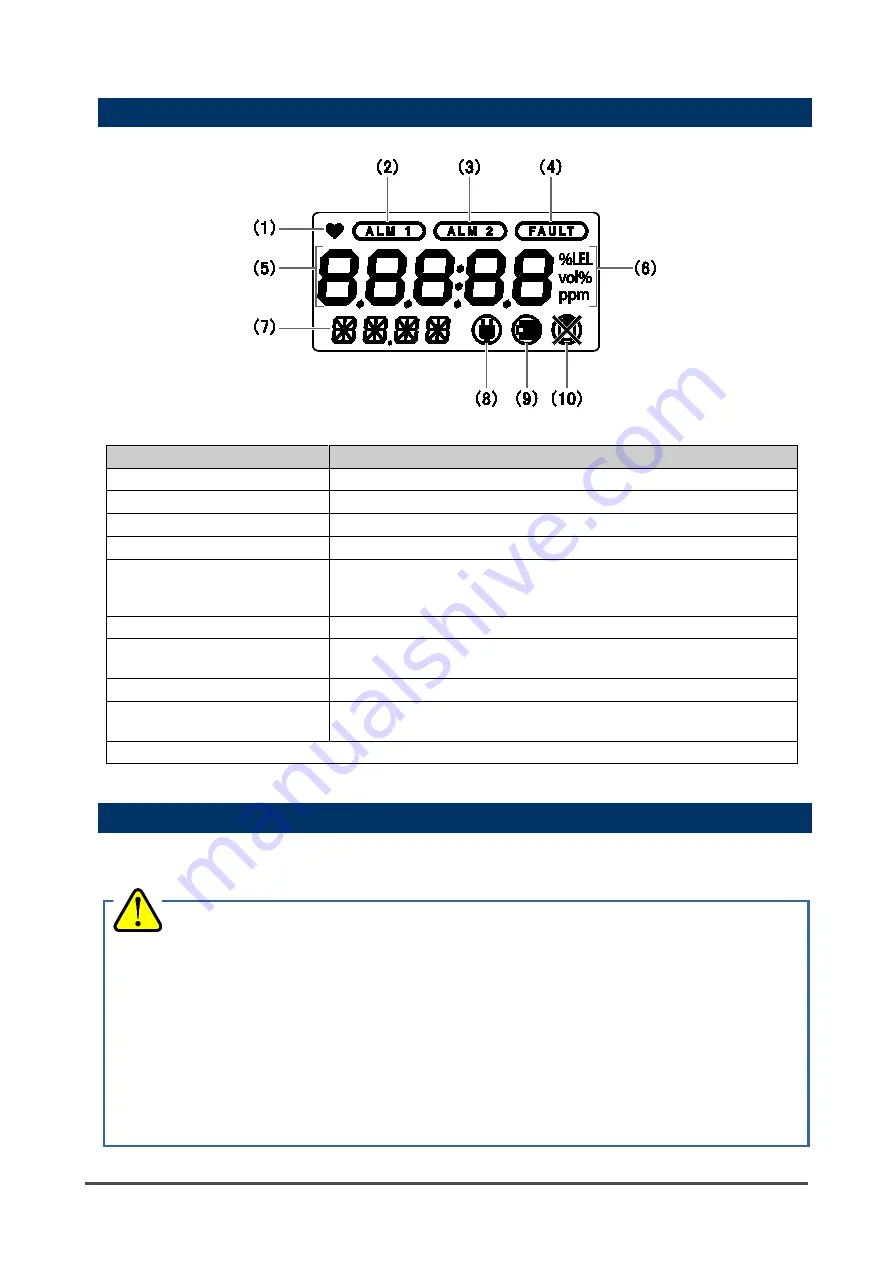

Display

Name

Major function

(1)

Operating state display

Displays the operating status. Blinks at a normal state.

(2)

1st alarm display

Lights up or flashes orange at a first alarm state.

(3)

2nd alarm display

Lights up or flashes red at a second alarm state.

(4)

Fault alarm display

Lights up in red at a fault alarm state.

(5)

Concentration value

display

Maintenance indicator

Displays the gas concentration.

Maintenance items and others are displayed during setup.

(6)

Unit display

Displays the unit (ppm) according to the specification.

(7)

Gas name display

Maintenance display

Displays the gas name.

Maintenance items and others are displayed during setup.

(8)

AC/DC power display

Lights up when the monitor is operating on AC or DC power.

(9)

Battery level icon

Displays the battery level when the monitor is operating on dry

batteries.

(10) This is not used for the monitor.

Installation of batteries (for dry battery type)

When the monitor is used for the first time, or when the battery level is low, install or replace with new AA

alkaline dry batteries according to the following procedure.

CAUTION

•

Turn off the power of the monitor before replacing the batteries.

•

Replace the batteries in a safe place where explosive gases are not present.

•

Never fail to use alkaline batteries. If a rechargeable (secondary battery) nickel-cadmium battery

or nickel metal hydride battery is used, the specifications cannot be met, such as continuous

operating time, etc.

•

Replace both batteries at the same time.

•

Pay attention to the polarities of the batteries when installing them.

•

After installing the batteries, lock the battery cover completely. If the battery cover is not

completely locked, the dry batteries may fall out.

•

Do not use rechargeable batteries that may interrupt a measurement due to the discharge

characteristic of rechargeable batteries.