WWW.RSIWW.COM

40 of 45

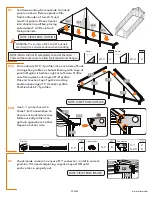

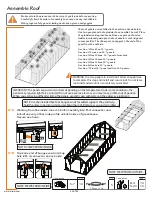

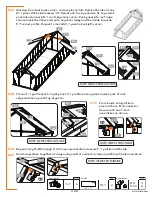

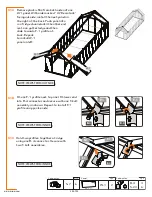

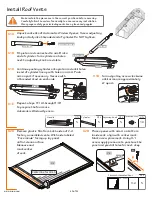

Install Roof Vents

Make certain the pieces are in the correct positions before securing.

Carefully follow the order of assembly to ensure an easy installation.

Wear proper safety gear including work shoes, gloves and goggles.

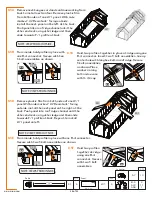

Unpack contents of Automatic Window Opener. Screw adjusting

knob partially into threaded end of cylinder. Do NOT tighten.

Fit piston rod connected to arm B into

end of cylinder. Turn cylinder so holes

next to adjusting knob are visible.

Continue pushing cylinder onto piston rod until holes

in end of cylinder line up with holes in arm A. Push

arms apart if necessary. Secure with

a threaded stud on each side.

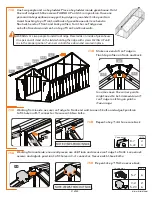

Repeat steps 9.1A through 9.1D

to prepare the four more

Automatic Window Openers.

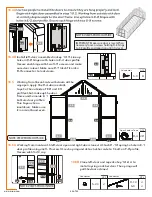

Remove plastic film from both sides of V-2

factory assembled vents. With side labeled

“ Face inside” facing up, lay panel

on flat clean surface.

Measure and

mark center

of vent.

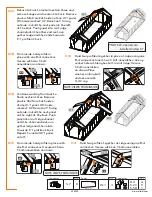

Place opener with arm A on bottom

inside vent, align with center mark.

Mark screw placement. Using S-1

screw, apply pressure to puncture the

panel and predrill holes for next step.

Turn adjusting screw clockwise

until arms are approximately

6” apart.

9.1A

9.1B

9.1c

9.1e

9.2A

9.2B

9.1D

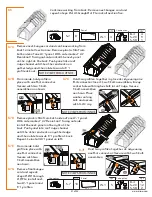

adjusting knob

cylinder

9.1B

piston rod

cylinder

arm B

arm A

QTY

Threaded Stud

10

QTY

Adjusting Knob

5

QTY

5

Cylinder

QTY

5

Handle

V-2

V-2

arm A

S-1

V-2

5

Factory Assembled Vent

QTY

24”

x

24

¾”

Center line for Arm A