64

●

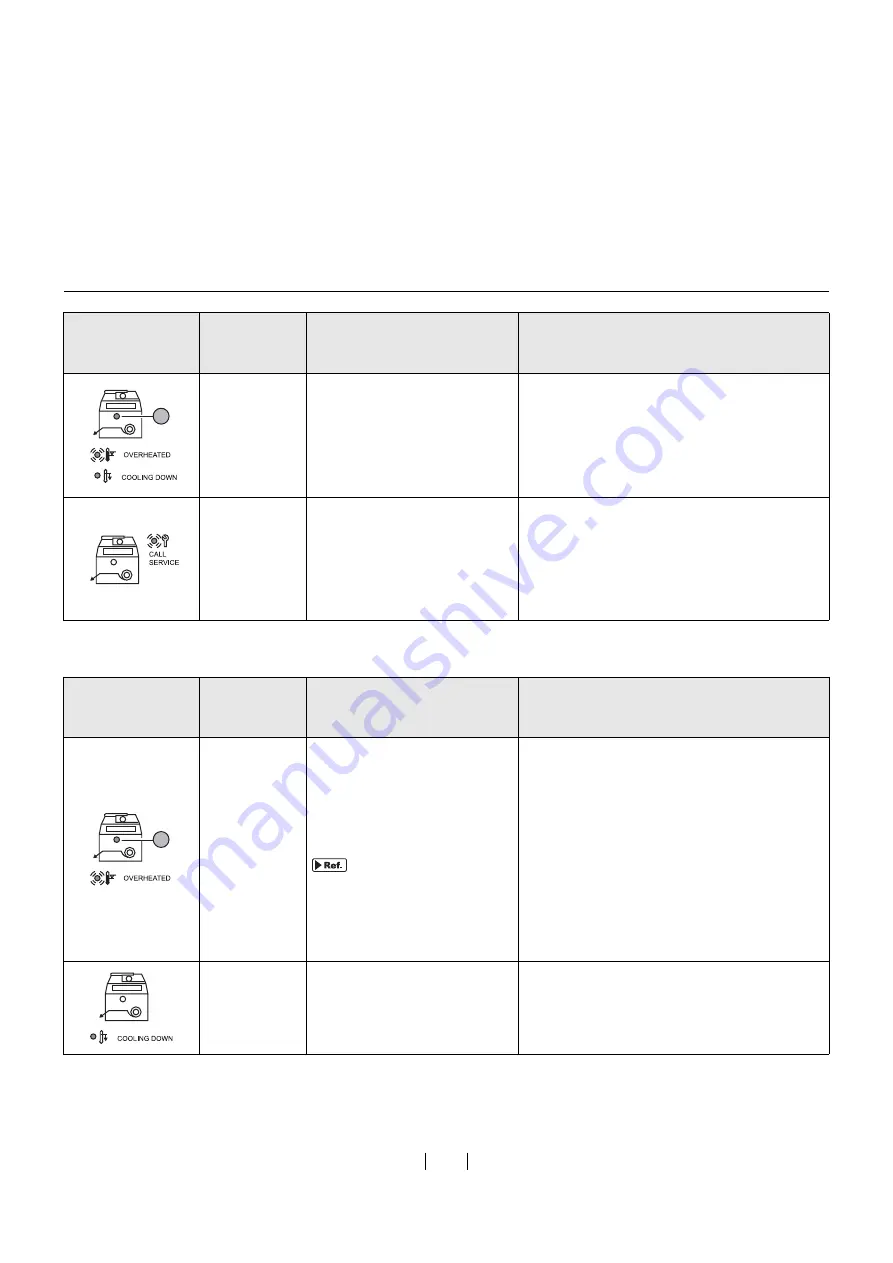

Other Indications

P-90

Overheating of the Thermal

Print Head.

Pre

ss

the <ALL RESET> Key to cancel the error.

The indicator change

s

from blinking (lit) to not

light.

The <COOLING DOWN> Indicator i

s

lit, and

the cooling-down operation i

s

s

tarted. When

the <COOLING DOWN> Indicator ha

s

gone

o

u

t, the

s

creen making can be re

su

med.

P-xx

Service Call Error occ

u

rred.

Try one of the following action

s

.

• Pre

ss

the <ALL RESET> Key to cancel the

error.

• T

u

rn off the machine, and then t

u

rn on the

machine.

When the machine doe

s

not operate de

s

pite

the above action, contact yo

u

r dealer.

Error Location

Indicator/Error

Type Indicator

Error No.

Error Description

Action

F-

3

4

Exce

ss

ive cover ratio.

The Thermal Print Head may

be overheated d

u

ring

s

creen

making.

"The Screen Making

Length and cover

Ratio" on page 44

To continue screen making

Pre

ss

the <START> Key.

To stop screen making

Perform the following action

s

.

1.

Pre

ss

the <ALL RESET> Key to cancel the

error.

2.

Pre

ss

the <ONLINE> Key to

s

witch to offline

mode, and delete the data in the

s

creen-

making q

u

e

u

e.

3.

Pre

ss

the <ONLINE> Key again to ret

u

rn to

online mode.

None

The temperat

u

re of the Thermal

Print Head ro

s

e.

The Thermal Print Head i

s

being cooled down.

When the <COOLING DOWN> Indicator goe

s

o

u

t, the next

s

creen making can be

s

tarted.

Error Location

Indicator/Error

Type Indicator

Error No.

Error Description

Action

3

3

Summary of Contents for GOCCOPRO 100

Page 1: ...User s Guide 053 36001 053 36003 Printed in Japan 2020 2...

Page 58: ...MEMO 56...

Page 59: ...Maintenance Maintenance page 58 Cleaning page 59...

Page 72: ...70 MEMO...

Page 93: ......

Page 94: ...Printed in Japan 2020 2...