21

OPERATION

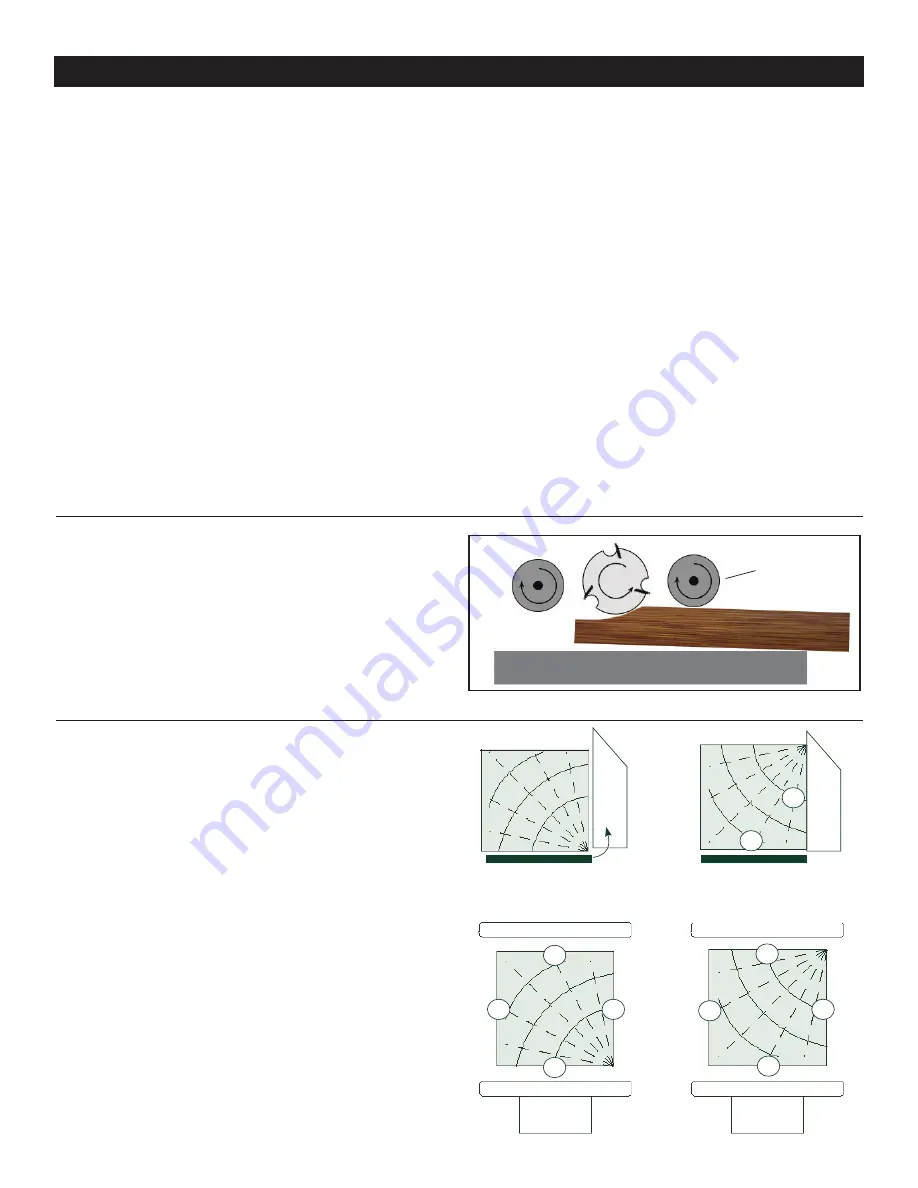

SNIPE

The term 'snipe' refers to the depression that may occur

at the front or rear of a board during planing. It is caused

by uneven pressure on the cutterhead when a board is fed

into the planer, or when exiting. FIG. 45.

Avoid snipe by keeping your lumber firmly down onto the

planer bed at the beginning of the cut, and also at the end

of the cutting action, as the lumber exits the planer.

FIG. 45

3. Set planing thickness. Measure your board's thickness

and set the planer to this measurement, or 1/16" under this

figure. For the initial pass, you do not want to take off an

excessive amount of stock (over 1/8"), or damage to the

planer may result. Repeated passes through the planer will

get you to your final desired board thickness. See page 14.

4. Feed boards slowly and straight into the planer. Boards

will be automatically fed through the planer by the infeed

and outfeed rollers.

- Guide work pieces straight into and through the planer.

The cutting action of the cutterhead may try to turn a board

being surfaced, so slight controlling of the board may be

necessary. Do not push the board forward, let the planer's

rollers automatically move the board through the machine.

5. Remove the board from the planer. Ref: Step 2, Do not

pull the lumber as it exits the machine. Let the out-feed

roller move the work piece out of the planer at its own rate,

but support the lumber as it extends past the extension

rollers, if needed.

Planer Operation - Continued from page 20

- Make sure that there are no loose knots, nails, staples,

dirt or foreign objects in the wood to be planed.

- Surface wood in the same direction of the grain, not

across the grain. Never plane end cuts or end grain.

- Do not plane boards that are less than 12" long. Short

boards should be planed end to end with other boards to

prevent kick-back and snipe.

- Boards longer than 60" should have additional support

as they enter and exit the planer, so that they do not tip up

or down, causing snipe on the ends.

- Run boards through the planer at different positions

along the width of the bed to utilize the full length of the

cutting knives. Planing only in the center, or through one

side of the planer, will quickly dull the knives in that area.

- To thickness plane stock with surfaces are not parallel,

use suitable feeding aids (make fitting templates).

SQUARING A WORK PIECE EXAMPLE

1. FIG. 46, A - On the jointer, surface side 1 flat.

2. B - After surfacing side 1, turn the work piece 90º so

that side 1 now rests against the fence. Joint side 2 flat.

The work piece will now have two sides at 90° to each

other.

3. C - Using the planer, run the work piece with side 1

positioned flat against the planer bed. The opposite side 3

can then be cut, and it will then be parallel to side 1.

4. D - Position side 2 flat against the planer bed, and side

4 will be planed flat, and be parallel to side 2.

The work piece will now be square, having four flattened

surfaces and four square edges.

1

2

FENCE

90º

1

FENCE

JOINTER

JOINTER

PLANER

BED

PLANER

BED

CUTTERHEAD

CUTTERHEAD

4

1

2

3

4

3

2

1

A

B

C

D

FIG. 46

FEED

ROLLER

PLANER BED

Summary of Contents for 25-010

Page 31: ...31 WARRANTY...