13

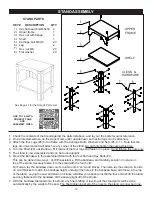

FIGURE 9

ADJUSTMENTS

ASSEMBLY

INSTALL THE GUIDE POST CAP

1. Place Guide Post Cap (#1A) into the square hole

on top of the upper frame. This cap protects the guide

post assembly from shop dust or debris. Fig. 10.

INSTALL THE PUSH STICK HOLDER

1. Assemble the Push Stick Hanger Bolt and Nut

(#50A, 51A) to the column’s left side with a 5mm hex

wrench. Handy storage for the push stick when not in

use. FIG. 9.

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN THE

OFF POSITION UNTIL ALL ADJUSTMENTS ARE COMPLETE.

TILTING THE TABLE

1. At the rear of the saw, loosen the Locking Handle

(#27B) on the table trunnion by turning it counter-

clockwise. Fig.11, A.

2. Turn the Table Tilting Knob (#30B) to adjust the

table to the desired angle. Fig. 11, B. Use the angle

indicator scale that is cast into the trunnion bracket

Support (#17B, C) to find the desired angle.

3. Retighten the locking handle to secure the table.

FIGURE 11

B

A

FIGURE 10

C

SETTING THE TABLE SQUARE TO THE SAW

BLADE’S SIDE

The table may be set at 90° to the saw blade sides

by adjusting the table stop Bolt (#8B) under the table.

The table stop bolt rests on the top of the pivoting

Stop Block (#33A). Fig. 12.

1. First loosen the bolt’s Locking Nut (#7B) Fig. 12, A.

2. Set a square on the table and against the saw

blade’s flat side. Tilt the table until the table is set ex-

actly 90° to the blade, then lock the table in position.

3. Adjust the bolt (Fig. 12, B), up or down, until it

is

in contact with the pivoting Table Angle Stop Block

(#33A) Fig. 12, C. Retighten the locking nut making

sure that the table angle setting is maintained.

FIGURE 12

4.

The angle indicator (#28B) on the trunnion, can

be adjusted by loosening the Phillips head screw and

moving the pointer into position. Fig. 12 D.

C

B

A

D

Summary of Contents for 10-324TG

Page 43: ...43 OPERATION...