19

20040563

GB

Installation

5.5.2

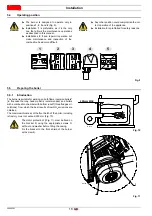

Boring the boiler plate

Pierce the closing plate of the combustion chamber, as in Fig. 12.

The position of the threaded holes can be marked using the ther-

mal insulation screen supplied with the burner.

Tab. I

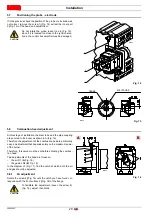

5.5.3

Blast tube length

The length of the blast tube must be selected according to the in-

dications provided by the manufacturer of the boiler, and in any

case it must be greater than the thickness of the boiler door com-

plete with its refractory.

The range of lengths available, L (mm), is as follows:

For boilers with front flue passes 13)(Fig. 13), a protection in re-

fractory material 11) must be inserted between the boiler refractory

12) and the blast tube 10). This protection must not compromise

the extraction of the blast tube.

For boilers with a water-cooled frontal, a refractory lining is not

necessary 11)-12) unless expressly requested by the boiler man-

ufacturer.

5.6

Securing the burner to the boiler

Separate the combustion head from the rest of the burner,

(Fig. 13). To do this, proceed as follows:

loosen the screw 3) and remove the hood 1);

remove screws 2) from the two slide bars 5);

disconnect the plug 14), unscrew the cable grommet 15);

remove the screw 4);

pull back the burner on the slide bars 5) by about 100 mm;

disconnect the wires from the probe and the electrode and

then pull the burner completely off the slide bars, after

removing the split pin from the slide bar 5).

Fix the flange 9) to the plate of the boiler interposing the

insulating gasket 8) supplied.

Use the 4 screws supplied, with a tightening torque of 35-40

Nm, after protecting their thread with anti-seize products.

mm

A

B

C

RS 55/E BLU

185

275 - 325

M12

Fig. 12

D455

Blast tube 10)

•

short

255

•

long

390

Provide an adequate lifting system of the burner.

WARNING

Before securing the burner to the boiler, check

(through the opening of the blast tube) that the

probe and electrode are correctly positioned, as in

Fig. 15.

WARNING

The seal between burner and boiler must be air-

tight: after the start-up, check there is no leak-

age of flue gases into the external environment.

Carry out all installation operations and mount the

casing again.

14

2

15

12

11

10

8

9

5

13

13

4

3

1

10

0

m

m

Fig. 13

D8149

Summary of Contents for RS 55/E BLU

Page 2: ...Translation of the original instructions Traducci n de las instrucciones originales...

Page 40: ......

Page 78: ...20040563 38 Appendix Ap ndice...

Page 79: ...39 20040563 Appendix Ap ndice...

Page 80: ...20040563 40 Appendix Ap ndice...

Page 81: ...41 20040563 Appendix Ap ndice...

Page 82: ...20040563 42 Appendix Ap ndice...