20182250

40

GB

Start-up, calibration and operation of the burner

6.12

Ignition failure

If the burner does not switch on, there is a lockout within 3s of the

electrical supply reaching the fuel valve.

It may be that the fuel does not arrive at the combustion head

within the safety time of 3s.

In this case increase fuel ignition flow rate.

6.13

Burner flame goes out during operation

If the flame accidentally goes out while running, the burner goes

into lockout within 1 second.

6.14

Stopping of the burner

The burner can be stopped by:

intervening on the disconnecting switch of the electrical sup-

ply line, located on the boiler panel;

using the “

0-AUTO

” switch of Fig. 32 on page 34.

6.15

Final checks

With the burner running

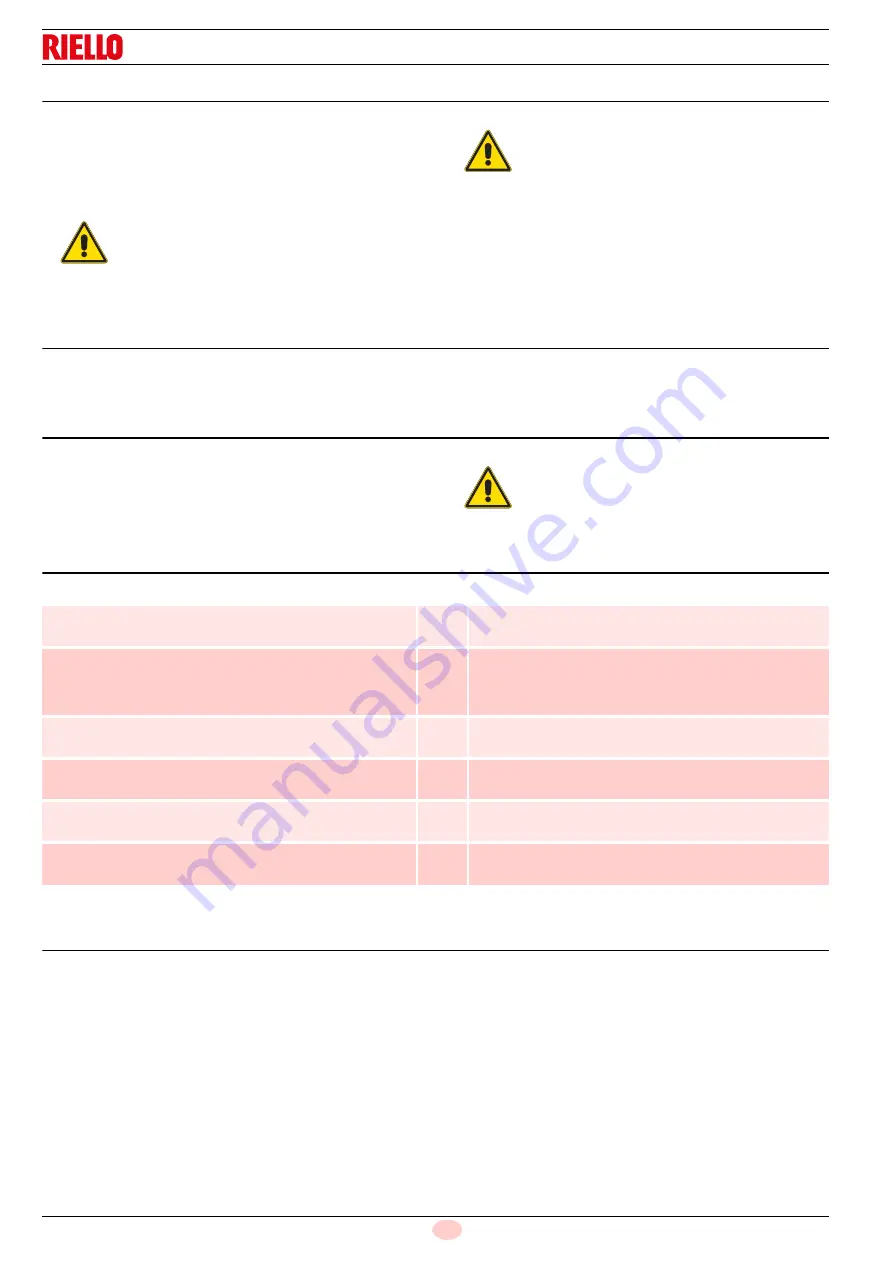

Tab. P

6.16

Pump motor lock-out

If the motor does not start, it could be because of a thermal relay

intervention due to its incorrect calibration or problems with the

motor or the main power supply, to release press the button of the

thermal relay, see “Calibration of the thermal relay” on page 20.

WARNING

In the event the burner stops, in order to prevent

any damage to the installation, do not unblock the

burner more than twice in a row.

If the burner locks out for a third time, contact the

customer service.

DANGER

In the event there are further lockouts or faults

with the burner, the maintenance interventions

must only be carried out by qualified, authorised

personnel, in accordance with the contents of this

manual and in compliance with the standards and

regulations of current laws.

WARNING

Make sure that the mechanical locking systems

on the various adjustment devices are fully tight-

ened.

Open the thermostat/pressure switch TL

Open the thermostat/pressure switch TS

the burner must stop

Turn the gas maximum pressure switch knob to the mini-

mum end of scale position

Turn the air pressure switch knob to the maximum end of

scale position

the burner must stop in lockout

Disconnect the minimum gas pressure switch connector

the burner must stop in lockout

Disconnect the maximum oil pressure switch connector

the burner must stop in lockout

Disconnect the minimum oil pressure switch connector

the burner must stop in lockout

Obscure the flame sensor

the burner must stop in lockout due to flame loss

Summary of Contents for RLS 310/EV O2 MX

Page 2: ...Translation of the original instructions ...

Page 52: ...20182250 50 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0 ...

Page 55: ...53 20182250 GB Appendix Electrical panel layout 0 ...

Page 56: ...20182250 54 GB Appendix Electrical panel layout ...

Page 57: ...55 20182250 GB Appendix Electrical panel layout 0 0 1 2 0 0 0 1 0 ...

Page 58: ...20182250 56 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 ...

Page 66: ......

Page 67: ......