15

20034293

GB

Installation

5.4

Installer/Servicer notes for the use of Gas oil with Bio blends up to 10%

During the burner installation, check that the gasoil and bio

fuel blends are in accordance with Riello specifications

(please refer to the chapters "Technical Data" and "Guid-

ance for the use of bio fuel blends up to 10%" within the

burner technical manual).

If a Bio blend is in use the installer must seek information

from the end user that their fuel supplier can evidence that

the blends of fuel conform to the relevant standards.

Check that the materials used in the construction of the oil

tank and ancillary equipment are suitable for bio fuels, If not

these must be upgraded or replaced with Bio compatible

parts.

Particular attention should be given to the oil storage tank

and supply to the burner. Riello recommends that existing

oil storage tanks are cleaned, inspected and any traces of

water are removed BEFORE bio fuel is introduced (Contact

the tank manufacturer or oil supplier for further advice). If

these recommendations are not respected this will increase

the risk of contamination and possible equipment failure.

In line oil filters should be replaced making sure that they

are Bio compatible. Riello recommends a good quality bio

compatible oil filter at the tank and a secondary 100 micron

filter are used to protect the burner pump and nozzle from

contamination.

The burner hydraulic components and flexible oil lines must

be suitable for bio fuel use (check with Riello if in doubt).

Riello have carefully chosen the specification of the bio

compatible components including the flexible oil lines to

protect the pump, safety value and nozzle. The Riello war-

ranty is dependent upon the use of Riello genuine compo-

nents including the oil lines, being used. The burner must

be commissioned and combustion parameters set to appli-

ance manufacturer's recommendations.

Regularly check visually for any signs of oil leakage from

seals, gaskets and hoses.

It is strongly recommended that with Bio fuel use, oil filters

are inspected and replaced every 4 months. More regularly

where contamination is experienced.

During extended periods of non operation and/or where

burners are using oil as a standby fuel, it is strongly recom-

mended that the burner is put into operation for shorts peri-

ods at least every three months.

5.5

Operating position

5.6

Preparing the boiler

5.6.1

Boring the boiler plate

Drill the combustion chamber locking plate as shown in Fig. 9.

The position of the threaded holes can be marked using the ther-

mal screen supplied with the burner.

Tab. H

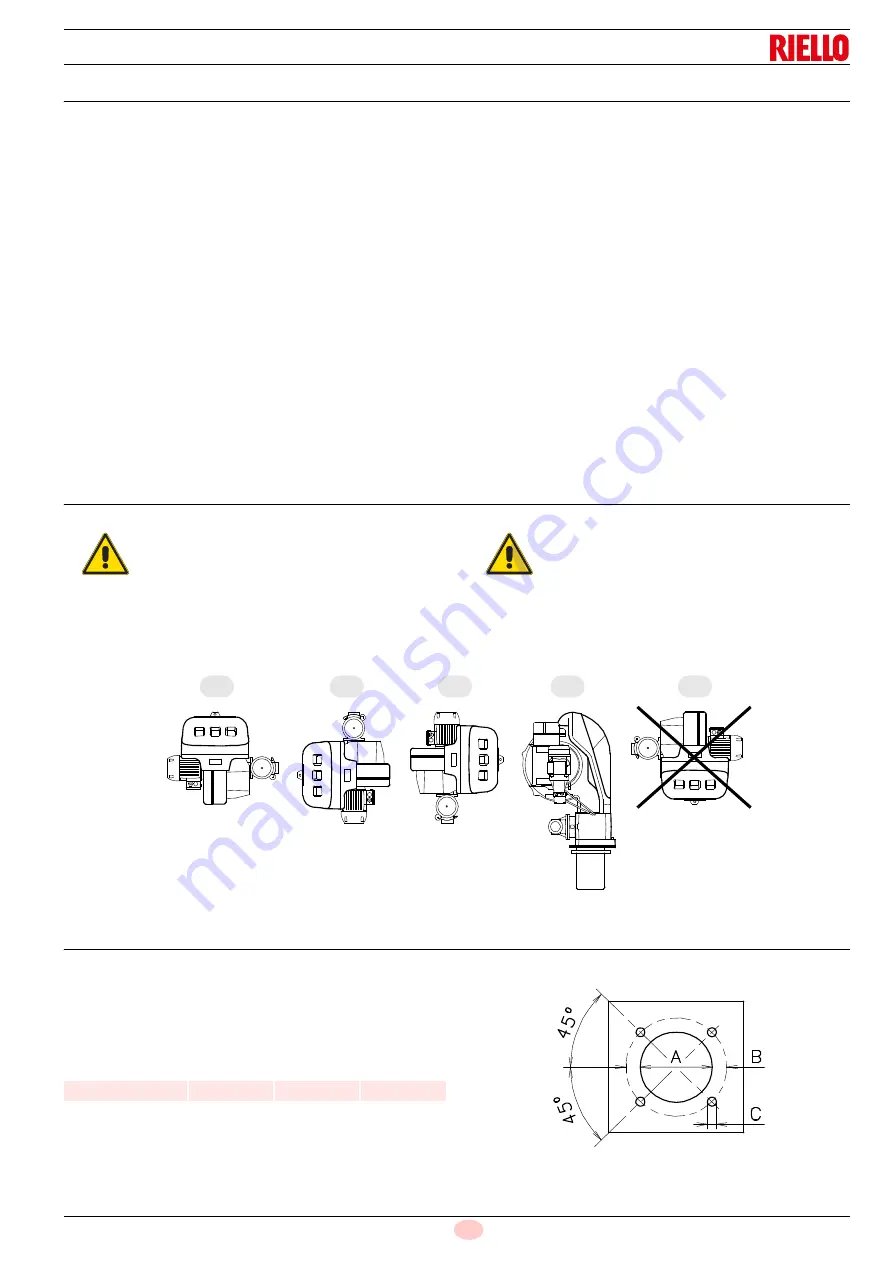

WARNING

The burner is designed to operate only in

positions

1

,

2

,

3

and

4

(Fig. 8).

Installation

1

is preferable, as it is the only

one that allows the maintenance operations

as described in this manual.

Installations

2

,

3

and

4

permit operation but

make maintenance and inspection of the

combustion head more difficult, pag. 33

DANGER

Any other position could compromise the cor-

rect operation of the appliance.

Installation

5

is prohibited for safety reasons.

Fig. 8

2

3

4

5

1

S8255

mm

A

B

C

RLS 250/M MZ

230

325 - 368

M 16

D455

Fig. 9

Summary of Contents for RLS 250/M

Page 2: ...Original instructions ...

Page 45: ...43 20034293 GB Appendix Electrical panel layout ...

Page 46: ...20034293 44 GB Appendix Electrical panel layout ...

Page 47: ...45 20034293 GB Appendix Electrical panel layout ...

Page 48: ...20034293 46 GB Appendix Electrical panel layout ...

Page 49: ...47 20034293 GB Appendix Electrical panel layout ...

Page 51: ......