20067636

14

GB

Technical description of the burner

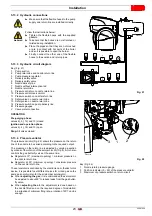

4.14 Control box for the air/fuel ratio (LMV52...)

Important notes

All interventions (assembly and installation operations,

assistance, etc.) must be carried out by qualified personnel.

Before modifying the wiring in the LMV52 control box con-

nection area, fully disconnect the system from the power

supply (omnipolar separation). Check the system is not

powered and cannot be accidentally reconnected. Failure to

do this will lead to the risk of electrocution.

Protection against electrocution from the LMV5... control box

and all connected electric components is obtained with cor-

rect assembly.

Before any intervention (assembly and installation opera-

tions, assistance, etc.), ensure the wiring is in order and that

the parameters are correctly set, then make the safety

checks.

Falls and collisions can negatively affect the safety func-

tions.

In this case, the control box must not be operated, even if it

displays no evident damage.

In programming mode, the position check of actuators and

VSD (checking electronic fuel / air ratio control) is different

from the check during automatic operation.

As for automatic operation, the actuators are guided

together to the positions requested and, if an actuator does

not reach the position requested, adjustments are made

until the position is actually reached. However, in contrast to

automatic operation, there are no time limits to these cor-

rective actions.

The other actuators maintain their positions until all actua-

tors have reached the positions currently required.

This is absolutely important to set the fuel / air ratio control

system.

During the time the fuel / air ratio curves are being pro-

grammed, the person making the plant settings must contin-

uously monitor the quality of the combustion process (e.g. by

means of a flue gas analyser).

Also, if combustion levels are poor, or in the event of dan-

gerous situations, the commissioning engineer must take

appropriate action (e.g. switching off manually).

To ensure the safety and reliability of the LMV5... system, the

following instructions must also be followed:

-

avoid conditions that can favour the development of conden-

sate and humidity. Otherwise, before switching on again,

make sure that the entire control box is perfectly dry!

-

Static charges must be avoided since they can damage the

control box’s electronic components when touched.

Mechanical structure

The LMV5... control box is a system to check the burners, based

on a microprocessor and equipped with components to adjust

and monitor medium and large capacity forced draught burners.

The base control box of the LMV5... system incorporates the fol-

lowing components:

• Burner control with gas valve proving system

• Electronic fuel / air ratio control with a maximum of 4

(LMV51…) or 6 (LMV52…) actuators

• Optional PID temperature / pressure controller (load control-

ler)

• Optional VSD module Mechanical design

Installation notes

• Check the electric wiring inside the boiler complies with the na-

tional and local safety regulations.

• Do not confuse the powered conductors with the neutral ones.

• Make certain that strain relief of the connected cables is in

compliance with the relevant standards (e.g. as per DIN EN

60730 and DIN EN 60 335).

• Ensure that spliced wires cannot get into contact with neigh-

bouring terminals. Use adequate ferrules.

• Arrange the HV ignition cables separately, as far as possible

from the control box and the other cables

• The burner manufacturer must protect unused AC 230V termi-

nals with dummy plugs (refer to sections Suppliers of other ac-

cessory items).

• When wiring the unit, make sure that AC 230V mains voltage

cables are run strictly separate from extra low-voltage cables

to avoid risks of electrical shock hazard.

WARNING

To avoid accidents, material or environmental

damage, observe the following instructions!

The LMV52 control box... is a safety device! Avoid

opening or modifying it, or forcing its operation.

Riello S.p.A. cannot assume any responsibility for

damage resulting from unauthorised interven-

tions!

Risk of explosion!

An incorrect configuration can provoke fuel over-

charging, with the consequential risk of explosion!

Operators must be aware that incorrect settings

made on the AZL5… display and operating unit

and incorrect settings of the fuel and / or air actu-

ator positions can lead to dangerous burner oper-

ating conditions.

Fig. 8

D9301

Summary of Contents for RLS 1600/EV C11

Page 2: ...Original instructions ...

Page 48: ...20067636 46 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0 ...

Page 49: ...47 20067636 GB Appendix Electrical panel layout ...

Page 51: ...49 20067636 GB Appendix Electrical panel layout ...

Page 52: ...20067636 50 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 53: ...51 20067636 GB Appendix Electrical panel layout 0 1 0 ...

Page 54: ...20067636 52 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1 ...

Page 55: ...53 20067636 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 4 ...

Page 56: ...20067636 54 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4 ...

Page 62: ......

Page 63: ......