20067636

36

GB

Maintenance

7.1

Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

7.2

Maintenance programme

7.2.1

Maintenance frequency

7.2.2

Checking and cleaning

Combustion

The optimum calibration of the burner requires an analysis of the

flue gases.

Significant differences with respect to the previous measure-

ments indicate the points where most care should be exercised

during maintenance.

Combustion head

Open the burner and make sure that all components of the

combustion head are in good condition, not deformed by the

high temperatures, free of impurities from the surroundings

and correctly positioned.

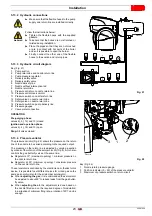

Voltage on the QRI cell

Min value for a good work: 3.5V DC (value on AZL display at

about 50%).

If the value is lower, it could be due to:

-

cell not positioned correctly

-

low voltage (lower than 187 V)

-

bad regulation of the burner

In order to measure, use a voltmeter with a 10V DC scale con-

nected as in the diagram (Fig. 44).

Burner

Clean the outside of the burner.

Fan

Check to make sure that no dust has accumulated inside the fan

or on its impellers, as this condition will cause a reduction in the

air flow rate and provoke polluting combustion.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially: the flue gas temperature and combustion cham-

ber pressure.

7

Maintenance

DANGER

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

DANGER

Turn off the burner's electrical supply using the

main system switch.

DANGER

Turn off the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

The gas combustion system should be checked at

least once a year by a representative of the man-

ufacturer or another specialised technician.

The operator must use the required equipment

during maintenance.

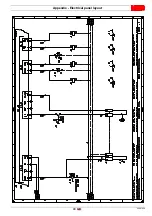

0...10 V

Ri > 10 M

:

X10-02 / 6

X10-02 / 4

X10-02 / 2

LMV...

+

D9174

Fig. 44

Summary of Contents for RLS 1600/EV C11

Page 2: ...Original instructions ...

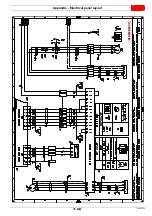

Page 48: ...20067636 46 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0 ...

Page 49: ...47 20067636 GB Appendix Electrical panel layout ...

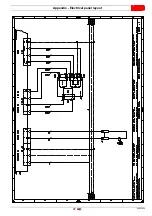

Page 51: ...49 20067636 GB Appendix Electrical panel layout ...

Page 52: ...20067636 50 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 53: ...51 20067636 GB Appendix Electrical panel layout 0 1 0 ...

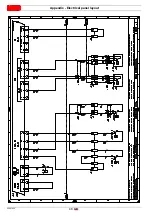

Page 54: ...20067636 52 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1 ...

Page 55: ...53 20067636 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 4 ...

Page 56: ...20067636 54 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4 ...

Page 62: ......

Page 63: ......