12

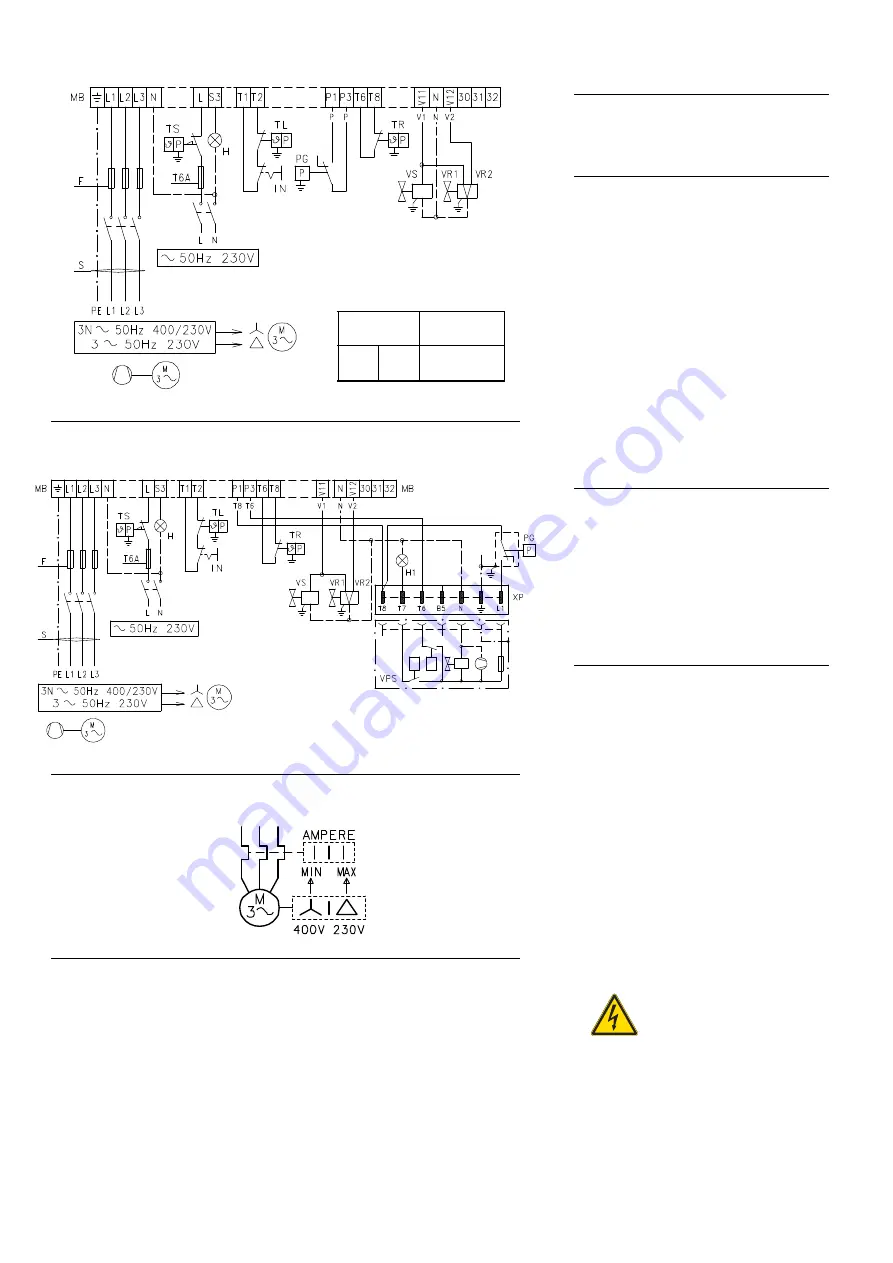

LAYOUT (A) - The GAS 9/2 Models electrical

connection three-phase power supply with-

out leak detection control device.

LAYOUT (B) - The GAS 9/2 Models electrical

connection three-phase power supply with

VPS leak detection control device.

Gas valve 8)-9)p. 10 leak detection control takes

place immediately before every burner starting.

KEY TO LAYOUTS

(A) - (B)

IN

- Manual burner stop switch

MB

- Burner terminal strip

PG

- Min. gas pressure switch

H

- Remote lock-out signal

H1

- Remote lock-out signal of leak detection

control device

TR

- High-low mode load control system:

controls operating stages 1 and 2.

If the burner is to be set up for single

stage operation, replace of remote con-

trol device TR with a jumper.

TL

- Load limit remote control system:

shuts down the burner when the boiler

temperature or pressure reaches the pre-

set value.

TS

- Safety load control system:

operates when TL is faulty

VR1 - Gas valve, stage 1

VR2 - Gas valve, stage 2

VS

- Safety valve

XP

- Plug for leak detection control device

LAYOUT (C)

Calibration of thermal cut-out 7)(A) p. 5

This is required to avoid motor burn-out in the

event of a significant increase in power absorp-

tion caused by a missing phase.

- If the motor is star-powered,

400 V

, the cursor

should be positioned to "MIN".

- If the motor is delta-powered,

230 V

, the cursor

should be positioned to "MAX".

Even if the scale of the thermal cut-out does not

include rated motor absorption at 400 V, protec-

tion is still ensured in any case.

N.B.

• Models GAS 9/2 three-phase leave the factory

preset for 400 V power supply. If 230 V power

supply is used, change the motor connection

from star to delta and change the setting of the

thermal cut-out as well.

• The GAS 9/2 burners have been type- ap-

proved for intermittent operation. This means

they should compulsorily be stopped at least

once every 24 hours to enable the control box

to check its own efficiency at start-up. Burner

halts are normally provided for automatically by

the boiler load control system.

If this is not the case, a time switch should be

fitted in series to IN to provide for burner shut-

down at least once every 24 hours.

• The GAS 9/2 burner is factory set for two-stage

operation and must therefore be connected to

control device TR.

Alternatively, if single stage operation is re-

quired, instead of control device TR install a

jumper lead between terminals 6 and 7 of the

terminal strip.

Do not invert the neutral with

the phase wire in the electric-

ity supply line. Inverting the

wires will make the burner go

into lock-out because of fir-

ing failure.

CALIBRATION OF THERMAL RELAY

(A)

(B)

ELECTRICAL CONNECTION OF BURNER BY INSTALLER

Without leak detection control device

ELECTRICAL CONNECTION OF BURNER BY INSTALLER

With VPS leak detection control device

Cable selection

GAS 9/2

230V

400V

F

S

A

mm

2

T 50

6

T 40

4

D2901

D2903

D867

(C)

DANGER

Summary of Contents for GAS 9/2

Page 2: ......