20013743

8

CN

燃料加热

为了保证燃烧器能顺利启动和整个出力范围内稳定运行,

燃烧器配置了加热器,以便加热喷嘴座中的燃油。

得到加热指令后电阻器通电加热,大约 2 分钟后 (根据室

温情况略有不同),风机电机开始转动。

燃烧器停机状态下,加热电器处于嵌入和锁定状态。

注意:

如果你想旁路该加热器

(

根据燃烧器设定或因为环境温

度已经合适不需再加热,等等 ...

)

,只需从控制盒上拔下

跳线插头然后插到

“Resistance OFF”

(加热

器旁路)

(

见图 .

8)

。

此时一旦温控开关闭合燃烧器立即

启动。

注意:

加热器工作时,报警指示灯

(LED)

会亮。电阻丝旁路或损

坏时指示灯不亮。

加热器故障检测

-

仅对

447T1

型号有效

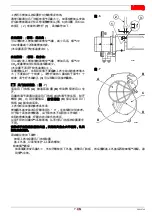

跳线插头插在

“Resistance ON”

位置

(

见图.

8)

。

得到启动指令后,

LED

指示灯亮,大约两分钟后燃烧器

启动。

1)

如果

LED

指示灯不亮,喷嘴座中的加热电阻丝可能

损坏。

2)

如果

LED

指示灯亮但是燃烧器不运行,将跳线插头

插到旁路位置

“Resistance OFF”

(

见图 .

9)

。如果电机启动,表明控制盒中的延时装置损坏。

3)

如果电机不转动,那么故障既不在于控制盒,也不在加

热器,而需要从其它方面找原因了。

电极调整

,

(

见图 .

10)

跳线插头

加热器工作

旁路加热器

LED

S7059

控制盒

531SE B

跳线插头

旁路加热器

S7060

LED

图

. 8

图

. 9

正常运行

燃烧器不运行

重要:

这些尺寸必须得到满足。

拆卸或安装喷嘴时,必须松开螺栓

(A)

并拆卸点火电极头部。

2 – 2.5

mm

4

±

0.3 mm

D5230

A

图

. 10

Summary of Contents for G5R MC

Page 13: ......

Page 14: ...20013743 CN Technical Assistance Centre Assistance Centre Maintenance Contract...

Page 17: ...3 20013743 CN 9 1 6 6 D5242 2 2 D5572 S7384...

Page 19: ...5 20013743 CN 1mm 4 1 2 1 2 1 2 1 D4677 A 531SE C E F FR P E H I M PE R TL TS Y 4...

Page 21: ...7 20013743 CN 6 6mm 2 1 CO2 CO2 3 1 3 7 A B C D D A 0 1 2 3 6 D5551 D C D5555 D A B 6 7 4...

Page 23: ...9 20013743 CN 120 D5329 120 12 12 5...

Page 24: ...20013743 10 CN CO2 CO ppm NOx ppm...

Page 25: ......

Page 26: ......

Page 27: ......