20013743

6

CN

燃烧调整

根据效率指令

92/42/EEC

对于使用在锅炉上的燃烧器,调整和测试必须根据锅炉的使用说明书来执行,包括

检验烟气中

CO

和

CO

2

的含量,烟气温度和锅炉内热水的平均温度。

为使燃烧器达到额定的出力,首先安装好合适的喷嘴,然后根据下表对燃烧头的位置和风门挡板开度进行设

置。

下表中的值在

CEN

锅炉上测试得到

(

根据欧盟燃油燃烧器

EN 267

标准

)

。

测试条件为

CO

2

浓度为

12.5%

,海平面高度,轻油,室温

20°C

。

推荐使用的喷嘴

:

Monarch R - NS

型;

Delavan W - A - E

型;

Steinen H - Q

型;

Danfoss H

型。

雾化角

:

60°

:

适应于多数情况。

80° :

适应于火焰分离,或低温点火情况。

油泵压力

12 bar :

出厂时的设置值。

14 bar :

提高火焰稳定性;也适应于低温点火情况。

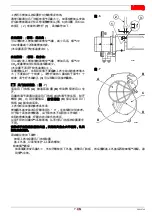

燃烧头的设置

:

安装喷嘴时设置,先拆下燃烧筒。

根据燃烧器最大出力来设置(如上表所示),通过旋转调

节杆来设置,直到燃烧筒的端面与设定 值刻度对齐。

图

5

中,燃烧头为 12bar 时

0.75 GPH

的出力而设

置,按上表要求,此时内风筒应设置在

2.5

。

喷嘴

油泵压力

燃烧器出力

燃烧头调整

风门挡板调整

GPH

雾化角

bar

kg/h ± 4%

设置点

设置点

0.60

60° / 80°

11

2.3

1.5

2

0.65

60° / 80°

12

2.6

2

2.2

0.75

60°

12

3.0

2.5

2.5

0.85

60°

12

3.4

3

3

1.00

60°

12

4.0

4

4.5

1.10

60°

12

4.4

5

6

1.25

60°

12

5.0

6

7

出厂设置值

0.75

60° S

12

3.0

2.5

2.5

1

2

3

4

1

2

D5582

2

1

3

5

燃烧筒

调节杆

内风筒

燃烧筒末端面

图

. 5

3

Summary of Contents for G5R MC

Page 13: ......

Page 14: ...20013743 CN Technical Assistance Centre Assistance Centre Maintenance Contract...

Page 17: ...3 20013743 CN 9 1 6 6 D5242 2 2 D5572 S7384...

Page 19: ...5 20013743 CN 1mm 4 1 2 1 2 1 2 1 D4677 A 531SE C E F FR P E H I M PE R TL TS Y 4...

Page 21: ...7 20013743 CN 6 6mm 2 1 CO2 CO2 3 1 3 7 A B C D D A 0 1 2 3 6 D5551 D C D5555 D A B 6 7 4...

Page 23: ...9 20013743 CN 120 D5329 120 12 12 5...

Page 24: ...20013743 10 CN CO2 CO ppm NOx ppm...

Page 25: ......

Page 26: ......

Page 27: ......