13

5

Preparation for start up

5.1

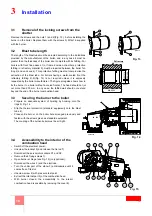

Combustion head setting

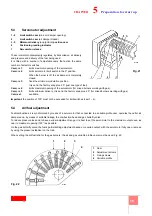

Loosen the screw 1) and turn the graduated sector 2) according dia-

grams Fig. 19.

The system allows an optimal setting even at a minimum firing rate.

Combustion head opening can be varied by moving the lever onto

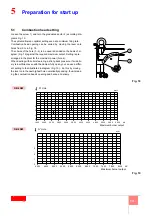

holes from 0 to 6, Fig. 18.

The choice of the hole (0 - 6) to be used is decided on the basis of di-

agram (Fig. 19) against the required maximum output. Setting is pre-

arranged in the plant for the maximum power (hole 6).

When dealing with boilers featuring a strong back pressure, if air deliv-

ery is insufficient even with the damper fully open, you can use a differ-

ent setting to that illustrated in diagram (Fig. 19) - do this by moving

the lever onto the next highest hole numerically speaking, thus increas-

ing the combustion head’s opening and hence air delivery.

Fig. 18

1

2

0

1

2

3

4

5

6

D8299

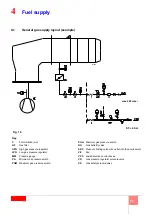

1600

2000

2400

2800

3200

3600

4000

4400

kW

4800

5200

3

2

1

0

5600

6000

N° Hole

Maximum burner output

Fig. 19

N° Hole

Maximum burner output

DB 6 SM

DB 4 SM

D7905

D8417

kW

7800

8200

7400

7000

6600

6200

5800

5400

5000

4400

4000

0

1

2

3

Maximum burner output

Summary of Contents for DB 6 SM CO1 A0

Page 2: ......

Page 43: ...1...

Page 44: ...2 1 3 3 3 2 4 4 4 5 6 8 9 3 10 10 10 10 10 4 11 11 12 5 13 13 14 15 15 17 18 18 6 19 19...

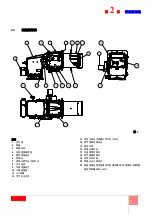

Page 47: ...5 2 2 3 1 2 3 4 5 6 7 8 9 10 11 UV 12 13 14 15 16 17 18 19 20 21 M12x16 2 20076243...

Page 49: ...7 2 DN 80 160 18 4 54 5 4 9 5 3 8 0 M18 D8325 7 8 D3974 9 D7549 DB6 SM...

Page 53: ...11 4 4 1 D7543 C GF HPG LPG MM PA PGM PGm RG SRV VE VPS VR VS 0 5 4 bar 500 mbar 16...

Page 54: ...12 4 4 2 MB PA PGM SM UV UV TA TB D9854 17...

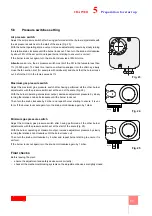

Page 56: ...14 5 5 2 20 20 20076847...

Page 57: ...15 5 5 3 1 4 2 3 5 6 7 1 2 0 3 20 4 5 20 130 1 4 5 4 130 22 21 D1500 3 2 4 1 22 1 2 3 4 D1499...

Page 58: ...16 5 MAN 3 1 130 90 2 22 2 22 20 2 2...

Page 60: ...18 5 5 7 70 A 187 V 100 A c c 100 F 1V c c 5 8 1 2 3 4 5 1 2 3 4 5 6 D1143 26...

Page 61: ...19 6 6 1 1 2 3 VR VR VS VR...

Page 62: ...20 6...

Page 63: ......