0ML190480RUENUC

page 3 / 24

TABLE OF CONTENTS

SECTION 1 ..................................................................................................... 3

INTRODUCTION ........................................................................................................................................................ 3

SECTION 2 ..................................................................................................... 5

SAFETY WARNINGS ................................................................................................................................................. 5

SECTION 3 ..................................................................................................... 8

BATTERY CABINET SETUP ................................................................................................................................... 8

FLOOR LOAD‐CARRYING CAPACITY ................................................................................................................ 8

CLEARANCE

S

............................................................................................................................................................... 8

HANDLING THE CABINET (unloading and transporting) ....................................................................... 8

INSPECTING THE EQUIPMENT ........................................................................................................................ 10

SECTION 4 ................................................................................................... 11

INSTALLATION AND ASSEMBLY OF BATTERY BLOCKS ....................................................................... 11

BATTERY ASSEMBLY MODE .............................................................................................................................. 11

REMOVE TRAYS ....................................................................................................................................................... 12

POSITIONING AND INSTALLING BATTERIES ............................................................................................ 12

TRAY ASSEMBLY PROCEDURE ......................................................................................................................... 13

CONNECTION BETWEEN THE TRAYS ........................................................................................................... 15

SECTION 5 ................................................................................................... 19

CONNECTION TO UPS SYSTEM ......................................................................................................................... 19

POWER CABLE CONNECTION ........................................................................................................................... 19

AUXILIARY CABLES CONNECTIONS (OPTION) ......................................................................................... 22

SECTION

1

INTRODUCTION

The BBX battery cabinet is used along with the Uninterruptible Power Supply (UPS), series MHT, to prevent

loss of valuable electronic information and minimize equipment downtime. During brownouts, blackouts, and

other power interruptions, batteries provide emergency power to safeguard operation.

Summary of Contents for MASTER HP

Page 1: ...UNINTERRUPTIBLE POWER SUPPLY MASTER HP UL 55 100Ah BATTERY CABINET User Manual ...

Page 2: ...0ML190480RUENUC page 2 24 RPS SpA Viale Europa 7 37045 Legnago VR Italy www riello ups com ...

Page 17: ...0ML190480RUENUC page 17 24 ...

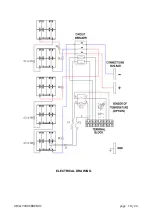

Page 18: ...0ML190480RUENUC page 18 24 ELECTRICAL DRAWING ...

Page 20: ...0ML190480RUENUC page 20 24 ...

Page 21: ...0ML190480RUENUC page 21 24 ...

Page 23: ...0ML190480RUENUC page 23 24 Fig 14 battery cabinet terminal block detail ...

Page 24: ...0ML190480RUENUC page 24 24 Fig 15 Connections diagram of auxiliary signals ...