Operating Instructions and Parts Manual

8

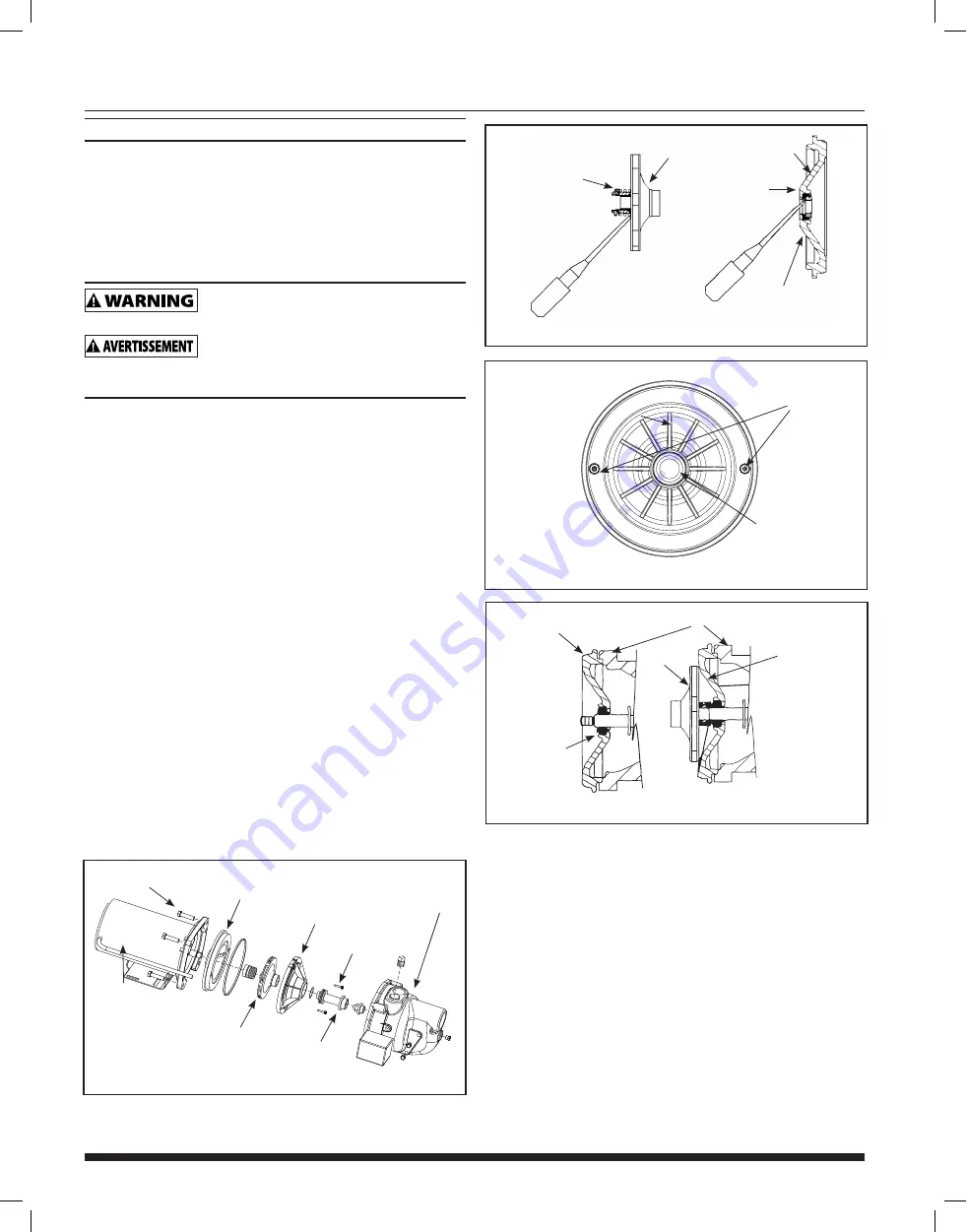

Figure 9 - Removing Shaft Seal and Ceramic Seat

ROTATING SHAFT

SEAL MEMBER

SEAL PLATE

CERAMIC SEAT

IMPELLER

RUBBER SEAT RING

Figure 10 - Seal Plate Replacement

SCREW

MOTOR

Figure 11 - Motor Shaft

SEAL PLATE

SEAL FACE

MUST BE

CLEAN FOR

PROPER SEAL

SEAL PLATE

MOTOR

IMPELLER

SEAL SEAT

KITS SECTION (CONT'D)

8. Remove the seal plate.

9. Pry the rotating shaft seal member (including stainless collar

and rubber seal) from the impeller (Figure 9).

10. Push or pry the ceramic seat, and rubber seat ring free from

the seal plate (Figure 9).

11. Remove loose particles from impeller hub and seal plate.

INSTALLING NEW SHAFT SEAL

Before handling shaft seal parts wipe hands

clean. Dirt or grease MAY damage the seal.

Se laver les mains avant de manipuler les

pièces du joint de l'arbre. La poussière ou la graisse POURRAIT

endommager le joint.

NOTE:

Be careful not to scratch the ceramic surface of the seal

seat and push seat enclosed in rubber into seal cavity on seal

plate. Use a cardboard washer to protect polished surface

when pushing against ceramic seat with any object. Be sure to

remove cardboard washer.

2. Carefully slip seal plate over shaft. Do not disturb seal position

in seal plate. The seal plate must be orientated during assembly

so the two screw holes are on a horizontal line across the

motor shaft (Figure 10). This placement should be done to

ensure proper draining and priming.

3. Place rotating shaft seal member in position on impeller and

press into place. Take care not to press against polished seal

surface.

4. Position impeller on shaft and tighten securely (Figure 11).

5. Secure diffuser to seal plate using the two cap screws. Be sure

the arrow on the front of the diffuser is pointing up and the

screws are orientated on a horizontal line as described in Step

2.

6. Carefully position pump housing (volute) gasket over the diffuser

onto the seal plate. In all shallow well applications care must

be taken that the o-ring is clean and properly positioned on the

venturi. Cleaning and positioning makes a good seal inside the

diffuser when assembled.

7. Assemble the pump housing (volute) to the motor using the

four cap screws. Be sure the pump housing (volute) gasket is

positioned correctly and tighten the screws securely.

NOTE:

Shaft must rotate freely and rear cover should be secured

before operation.

Figure 8 - Shaft Seal

CAP SCREWS

DIFFUSER

PUMP HOUSING

(VOLUTE)

CAP SCREWS

SEAL PLATE

MOTOR

IMPELLER

VENTURI