The causes and solutions of Bad images

G186 4-10 SM

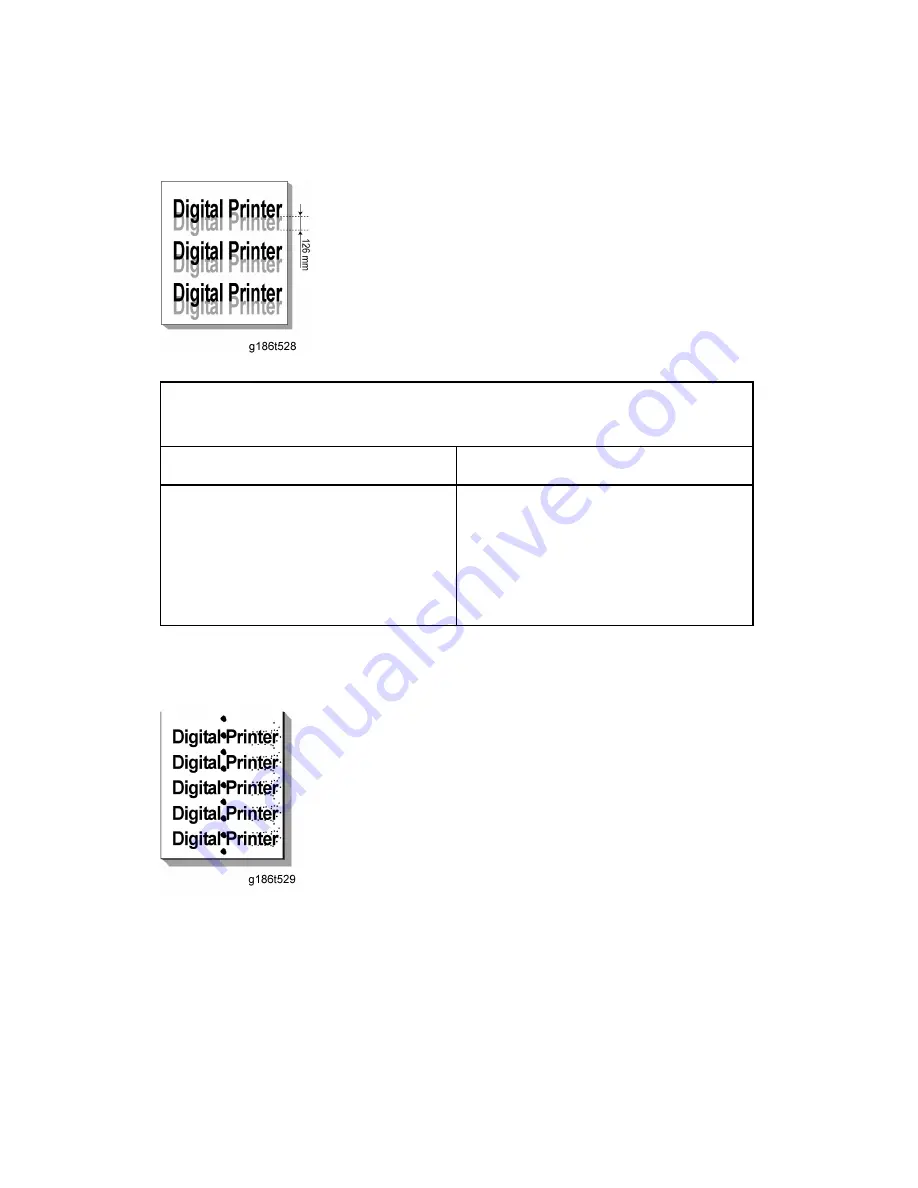

4.2.11 GHOST (3): FUSER

Description:

Ghost occurs at 126 mm intervals.

Check and Cause

Solution

The temperature of the fuser is maintained

at a high temperature.

Disassemble the fuser and remove the

contaminated toner particles on the roller,

and clean out the foreign matter between

the thermistor and heat roller.

(Caution: can be deformed)

4.2.12 STAINS ON THE FACE OF PAGE

Summary of Contents for Aficio SP 5100N

Page 1: ...G186 SERVICE MANUAL 003108MIU...

Page 2: ......

Page 3: ...G186 SERVICE MANUAL...

Page 4: ......

Page 5: ...G186 SERVICE MANUAL 003108MIU...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 18: ......

Page 26: ......

Page 27: ...INSTALLATION...

Page 28: ......

Page 30: ......

Page 31: ...PREVENTIVE MAINTENANCE...

Page 32: ......

Page 34: ......

Page 35: ...REPLACEMENT AND ADJUSTMENT...

Page 36: ......

Page 84: ......

Page 85: ...TROUBLESHOOTING...

Page 86: ......

Page 117: ...SERVICE TABLES...

Page 118: ......

Page 136: ......

Page 137: ...DETAILED SECTION DESCRIPTIONS...

Page 138: ......

Page 156: ......

Page 157: ...SPECIFICATIONS...

Page 158: ......

Page 163: ...APPENDIX...

Page 164: ......

Page 165: ...Block Diagram SM 8 1 G186 Appendix 8 APPENDIX 8 1 BLOCK DIAGRAM 8 1 1 SYSTEM BLOCK DIAGRAM...

Page 166: ...Block Diagram G186 8 2 SM...

Page 167: ...Connection Diagram SM 8 3 G186 Appendix 8 2 CONNECTION DIAGRAM...