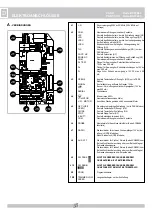

G

B

29

29

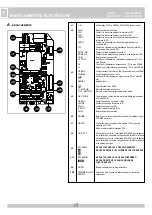

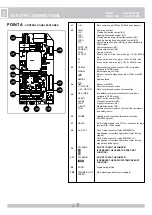

RELAY AND MOTOR COMMAND

K1 => Opening direction command

K2 => Closure direction command

Q4 => TRIAC - Opening and Closing motor command

Q5 => Blinker command

POINT B

- SETTINGS

DIP 1 (ON) MOTOR ROTATION DIRECTION CHECK

(See Point C)

DIP 2 (ON) PROGRAMMING (See Point D)

DIP 1-2

STORING/ERASING RADIO CODES FOR

MOTOR CONTROL (only CRX control board)

(See Point E)

DIP 3

ON - Automatic Closing ENABLED (max 5 min)

OFF - Automatic Closing DISABLED

DIP 4

ON - AUTOMATIC Radio Receiver Command

OFF - STEP BY STEP Radio Receiver Command

DIP 5

ON - AUTOMATIC single pulse command (K BUTT.)

OFF - STEP BY STEP single pulse command (K BUTT.)

DIP 6

ON - Operation in PARK MODE

OFF - Operation in NORMAL MODE

WARNING: The PARK MODE enables or disables some features and

commands:

If NORMAL MODE is enabled, OPEN2 command, OK CLOSE

command and TLC (Traffic Light Control) input, are not

enabled.

If PARK MODE is enabled all commands are enabled.

DIP 7

ON - boom arm locking magnet ENABLED (ACQ9080 or

ACQ9081 optional cards)

OFF - courtesy light operation ENABLED (ACQ9080 or ACQ9081

optional cards)

If none of the optional card is connected, turn DIP7 to OFF.

DIP 8

ON - in PARK MODE the OPEN2 button is always enabled

OFF - in PARK MODE the OPEN2 button works if there is no

vehicle on the magnetic sensor connected to the TLC input

(TLC contact opened).

DIP 9

ON - safety strip self-test ENABLED

OFF - safety strip self-test DISABLED

DIP 10

ON - after the blackout the boom arm automatically closes

OFF - after the blackout the boom arm remains still on the point it

was when blackout occurred

DIP 11

OFF for RAPID PARK barrier

DIP 12 OFF - Operation control with low speed limit switches

connected separately LIMIT SWITCHES FIXED ON THE

BALANCE SPRING BARS (for PARK control panel)

ON - Operation control with low speed limit switches

connected in parallel LIMIT SWITCHES FIXED ON THE

DRIVING SHAFT (the low speed wire can be connected

to LSSC or LSSO)

DIP 13

ON - Blinker operation with intermittent power supply

OFF - Blinker operation with fixed power supply

DIP 14

OFF for RAPID PARK barrier

DIP 15

ON for RAPID PARK barrier

DIP 16

OFF for RAPID PARK barrier

LOW SPEED REGULATOR

Slow-speed regulations are carried out by turning the Trimmer LOW

SPEED, it permits to vary the speed of the motor in approaching to the

closing position (turning clockwise to increase the motor speed). This kind

of regulation is not available in approaching to the opening position.

The starting of slowing down is controlled automatically by the limit

switches at approximately 30° before reaching the complete opening and

closing position.

LED WARNING

DL1 - Programming activated (red)

DL2 - Stop contact (red)

DL3 - Barrier opening (green)

DL4 - Barrier closing (red)

DL5 - Photocells contact (red)

DL6 - Safety strip contact (red)

DL7 - Closing limit switch contact (red)

DL8 - Opening limit switch contact (red)

DL9 - Radio programming activated (green) (CRX models only)

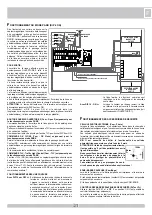

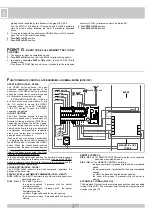

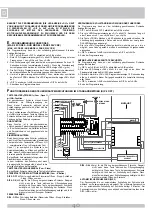

POINT C

- CALIBRATING LOW SPEED MOTOR

This check is meant to facilitate the installer during the start-up of the

system or for any other future controls:

1 -

Turn DIP1 to ON

, the red led DL1 starts blinking

2 -

Press the PROG button

and hold it (movement is now performed in

“man present” mode, open-stop-close-stop-open etc.).

If the GREEN led DL3 is on, the boom arm opens. If the RED led DL3

is on, the boom arm closes.

3 -

Carry out the slow-down speed calibration:

- Turn the LOW SPEED trimmer to minimum

- Press and hold the PROG button pressed

-

Check whether the low speed has been enabled once LSSC and

LSSO limit switches have been reached

- Adjust the LOW SPEED trimmer

WARNING:

Make sure the motor is powerful enough to move the bar

during closure. Otherwise increase the value set on the LOW SPEED

trimmer until it reaches the ideal operation condition.

4 -

Turn DIP1 to OFF

, the red LED DL1 turns off.

During Point C procedure the safety-strip and photocells are not

enabled.

POINT D

- TIME PROGRAMMING

1 - Close the barrier completely.

2 -

Turn the DIP 2 to ON

, the red led DL1 starts blinking.

3 -

Press the PROG button

, the boom arm opens.

4 -

Once opening has been completed, the boom arm stops. The gap of

time between now (stop of the motor) and the next pressing of the

PROG button (see step 5 below) will be then stored as waiting time

(max 5 minutes) for Automatic Closing feature.

5 -

Press the PROG button

, the boom arm closes and the Automatic

Closing time is stored (see DIP3 function to enable or disable the

Automatic Closing feature).

6 -

The red LED DL1 turns off.

7 -

Turn DIP2 to OFF.

During Point D procedure, the safety devices (photocells and safety

strip) are active.

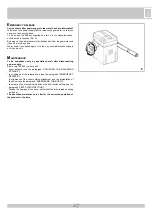

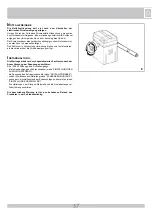

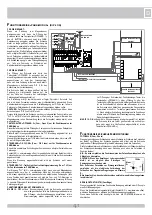

POINT E

- RADIO CODE STORING (ONLY FOR CRX)

(MAX 60 CODES)

1 - The boom arm must be completely closed.

2 -

Turn DIP1 to ON

position, the red LED DL1 starts blinking quickly

3 - Immediately,

turn also DIP2 to ON position

, the red LED DL1 starts

blinking slowly. Each code must be programmed within 10 seconds.

4 - Press one of the buttons on the remote control (usually channel

A). If the remote control is stored correctly green LED DL9 (on the

PARK230V CRX control board) emits a flash. The 10 seconds’ time

within storing radio codes is automatically renewed to allow the string

of the next remote control.

5 - To end radio code storing either press PROG button or let 10 seconds

pass. The LED DL1 shall stop blinking.

6 -

Turn DIP1 to OFF

position.

7 -

Turn DIP2 to OFF

position.

POINT F

- RADIO CODE ERASING (ONLY FOR CRX)

1 - The boom arm must be completely closed.

2 -

Turn DIP1 to ON

position, the red LED DL1 starts blinking quickly

3 - Immediately,

turn also DIP2 to ON

position, the red LED DL1 starts

blinking slowly. Code erasing must be carried out within 10 seconds.

4 -

Press the PROG button

and hold it for 5 seconds, the total memory

Summary of Contents for AA50037K

Page 55: ...55 55 NOTES ...