36

ADJUSTING SCREW

+ = MORE GAS

– = LESS GAS

GAS

INLET

F10330

Figure 41. Gas Valve

Visual Inspection

Flames can be observed through the sight glass next to the

igniter. A blue colored flame indicates normal operation.

At least every three months a visual inspection should be

made.

Electrical

Be sure that electrical service to the heater has proper

overload fuse or circuit breaker protection, wire size and

connections which comply with all applicable codes.

CAUTION:

Prior to replacing any component, make

sure that the main gas, power, and pumps are turned

OFF.

Orifice Removal

The gas orifice is located on the gas train, between the gas

valve and the combustion blower.

1.

Locate and close the external manual shutoff valve.

2.

Loosen the external gas union.

3.

Locate and remove front door panel.

4. Locate and remove the (4) bolts & nuts holding the

gas orifice in place. See the figure above.

5.

Carefully remove the gas orifice and do not misplace

the o-rings attached to the flanges.

6.

Inspect and/or replace the orifice with the correct

size.

GAS MANIFOLD

PRESSURE TAP

GAS ORIFICE

O-RING

F10347

Figure 42. Gas Train

Combustion Settings

Verify that the gas orifice matches the fuel type supplied.

The natural brass finish orifice is for natural gas and the

black oxide finish orifice is for Propane.

Table K

shows the

desired ranges for CO

2 % and limits for CO ppm. Follow

the instructions from the Adjusting Valve Manifold Pressure

section to make adjustments. Desired CO

2 % and max CO

ppm apply to all firing rates, but firing rate must be stable

for a good reading (fan RPM should not change more than

50 RPM while taking a sample).

Fuel Type

CO

2

Range (%)

CO Max (PPM)

Natural Gas

8.6 – 9.2

100

Propane

9.5 – 10.1

100

Table O. Combustion Settings

NOTE:

Orifices for propane gas have a black oxide

finish

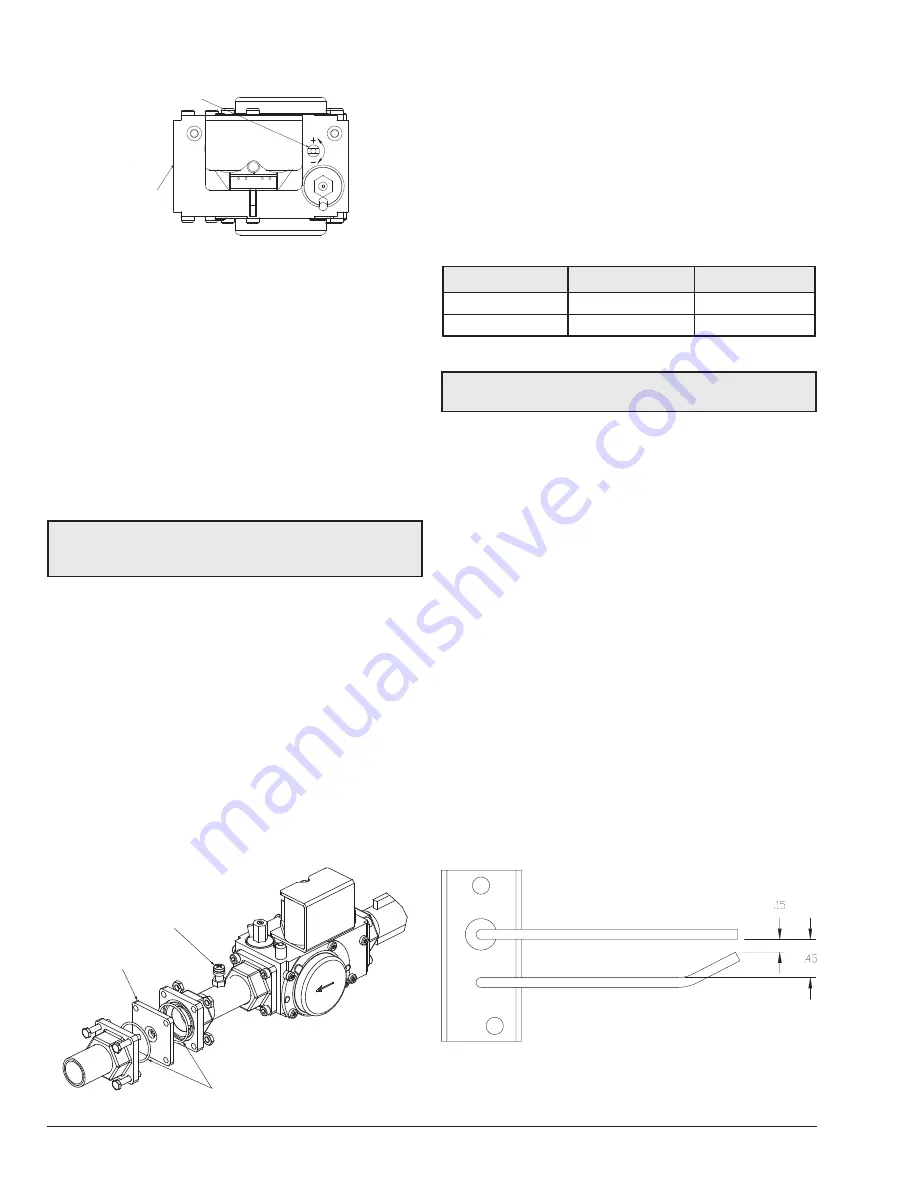

Igniter Removal

1.

Locate and remove the top panel.

2.

Locate the igniter in front of the blower and burner.

3.

Locate and disconnect the high tension spark cable

from the igniter.

4. Using a 5/16” (8 mm) socket, remove the (2) bolts

holding the igniter down.

5. Using a flat screw driver, loosen the igniter bracket

from the combustion chamber, preferably on both

sides.

6.

Carefully remove the igniter from its location. In order

to remove the igniter without damaging the refractory,

it is necessary to rotate the igniter 90 degrees

clockwise before lifting it out of the heater.

7. When replacing or inspecting the igniter, the gap

between the ground & spark tips should be 0.15”±

0.01” (3.81± 0.25 mm). The gap between the spark

and ground rods should be uniform and the rods

should not be distorted. Inspect the ceramic insulator

at the base of the spark rod carefully for cracks,

replace the igniter if any defects are found.

Figure 43. Igniter

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

Summary of Contents for Raypak X94 SR-410

Page 26: ...26 5 WIRING DIAGRAM APPROVED UNCONTROLLED DOCUMENT IF PRINTED...

Page 42: ...42 Control Logic Flow Chart Pool Spa Modes APPROVED UNCONTROLLED DOCUMENT IF PRINTED...

Page 43: ...43 10 ILLUSTRATED PARTS LIST APPROVED UNCONTROLLED DOCUMENT IF PRINTED...

Page 51: ...51 NOTES APPROVED UNCONTROLLED DOCUMENT IF PRINTED...