The importance of proper air flow over the heat exchanger cannot

be over emphasized .

One of the most common causes of heat exchanger failure is

overheating due to low air flow . An air flow table is located inside

the blower door and on the following pages .

TEMPERATURE RISE CHECK

To determine if the air flow is correct, make a temperature rise

check .

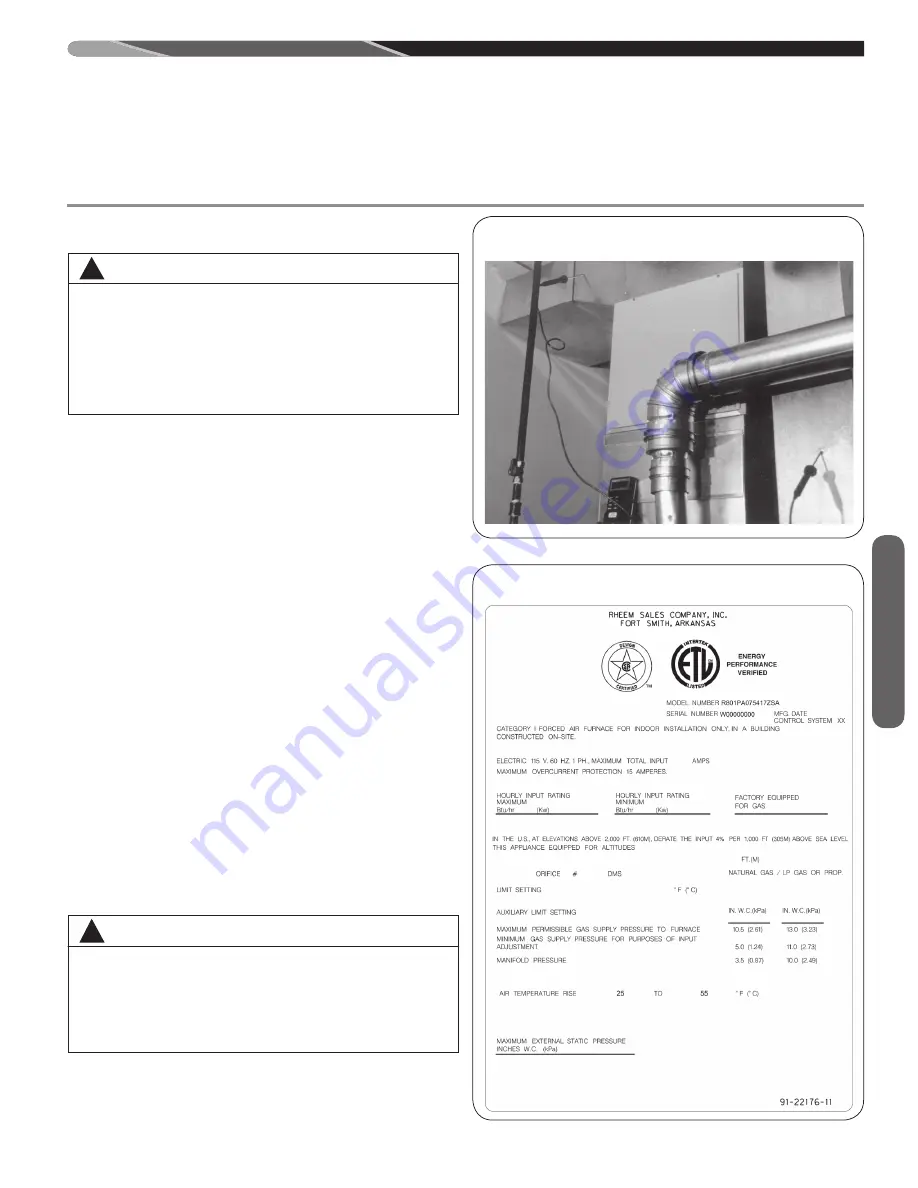

1 . Insert a thermometer in the supply air duct as close to the

furnace as possible yet ot of a direct line from the heat ex-

changer . See Figure 31 .

2 . Insert a thermometer in the return air duct as close to the fur-

nace as possible .

3 . Operate the furnace .

4 . When the thermometer in the supply air duct stops rising (ap-

proximately five minutes), subtract the return air temperature

from the supply air temperature . The difference is the tem-

perature rise .

5 . Compare the measured temperature rise to the approved

temperature rise range listed on the furnace name plate . See

Figure 32 .

If the measured temperature rise is below the nameplate range,

the gas input rate may need to be adjusted or the airflow may be

too high . If the gas input is correct, select the next lowest speed

tap for the heating function . If the measured temperature rise is

above the nameplate range, the gas input rate may need to be

adjusted or the duct system may be too restrictive due to under-

sized ducts . An undersized return duct is a common cause of an

overly restrictive duct system .

IMPORTANT: The measured temperature rise should be in the

middle of the range.

IMPORTANT: Some high-efficiency filters have a greater than

normal resistance to airflow. This can adversely affect furnace op-

eration. BE SURE TO CHECK AIRFLOW if using any filter other

than factory-provided filter.

45

Airflow

AIRFLOW

!

CAUTION

IT IS IMPORTANT THAT EACH DUCT SYSTEM BE SIZED

AND INSTALLED FOR THE SPECIFIC APPLICATION BY

PROPERLY APPLYING THE APPROPRIATE INDUSTRY

ACCEPTED STANDARD . IF LESS THAN MINIMUM STAN-

DARDS ARE APPLIED, THE EQUIPMENT USER COULD

EXPECT TO EXPERIENCE HIGHER UTILITY BILLS,

MAJOR COMPONENT FAILURE, VARYING DEGREES OF

AIR NOISE OR OTHER UNSATISFACTORY ISSUES, OVER

WHICH THE MANUFACTURER HAS NO CONTROL .

FIGURE 31

TEMPERATURE RISE MEASUREMENT

WARNING

THE MEASURED TEMPERATURE RISE MUST BE WITHIN

THE TEMPERATURE RISE RANGE SPECIFIED ON THE RAT-

ING PLATE . OPERATING THE UNIT WITH A RISE OUTSIDE

THE STATED RANGE COULD CAUSE DAMAGE TO THE

HEAT EXCHANGER OR INTERMITTENT OPERATION .

THIS COULD CAUSE INJURY OR DEATH AND WILL VOID

THE MANUFACTURER’S WARRANTY FOR THIS PRODUCT.

FIGURE 32

TYPICAL FURNACE NAME PLATE

!

Summary of Contents for 801C Series

Page 52: ...52 CM 0917...